Efficient Conveyor Belt for Beverage Transportation

By:Admin

In today's fast-paced beverage industry, efficient and reliable transportation of products is essential for the success of any company. This is why the new conveyor belt for beverage transport from {} has been generating a lot of buzz in the market.

{} is a leading manufacturer of conveyor systems and automation solutions with a strong commitment to innovation and customer satisfaction. Their conveyor belt for beverage transport is designed to meet the unique needs of beverage production and distribution, providing a seamless and efficient solution for moving beverages from one part of the production line to another.

The company has a long history of providing high-quality conveyor systems for various industries, and their expertise in the beverage industry is second to none. With a focus on precision engineering and advanced technology, {} has developed a conveyor belt that is specifically tailored to the needs of beverage manufacturers.

One of the key features of this conveyor belt is its ability to handle a wide range of beverage products, including bottles, cans, and cartons. This versatility makes it an ideal solution for companies that produce a variety of beverages and need a reliable and flexible transportation system.

In addition to its versatility, the conveyor belt for beverage transport from {} is also designed for fast and efficient operation. With a high-speed motor and precision control system, it can move beverages along the production line with minimal downtime, contributing to higher productivity and lower operational costs.

Furthermore, the conveyor belt is constructed with food-grade materials that comply with industry standards for hygiene and safety. This ensures that the quality and integrity of the beverages remain intact throughout the transportation process, meeting the strict regulatory requirements of the industry.

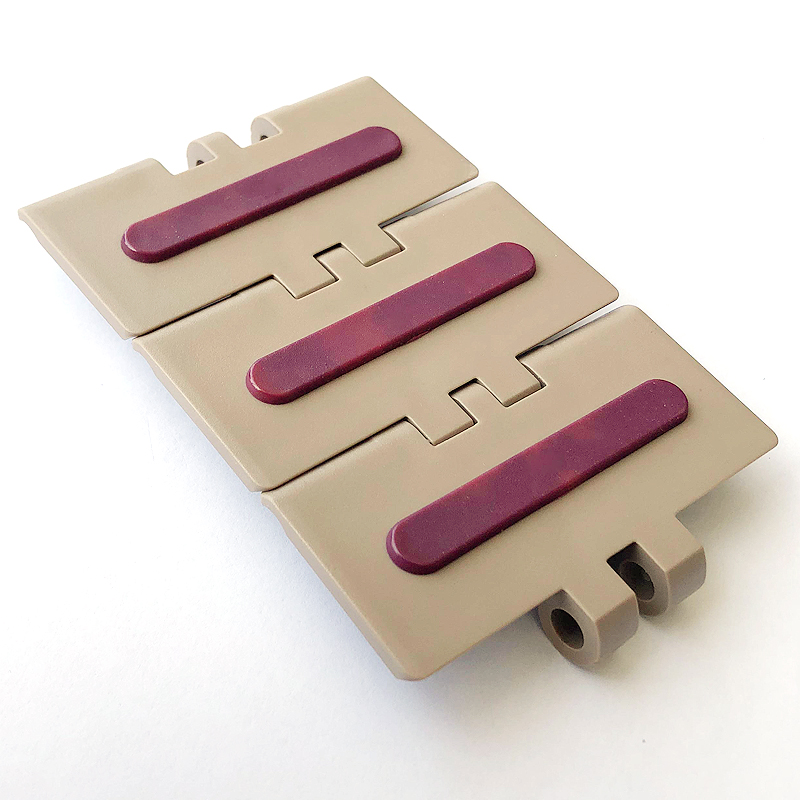

Another notable feature of the {} conveyor belt is its modular design, which allows for easy installation and maintenance. This modular approach also enables companies to customize the conveyor system to their specific production needs, making it a highly adaptable solution for beverage manufacturers of all sizes.

The company also provides comprehensive support and service for their conveyor belt, ensuring that customers receive ongoing assistance to keep their systems running smoothly. With a team of experienced engineers and technicians, {} is committed to helping their clients maximize the performance and longevity of their conveyor systems.

As the beverage industry continues to evolve and grow, the demand for efficient and reliable transportation solutions will only increase. With its conveyor belt for beverage transport, {} is well-positioned to meet this demand and help beverage manufacturers streamline their production processes.

In conclusion, the conveyor belt for beverage transport from {} represents a significant advancement in conveyor technology for the beverage industry. With its innovative design, high-speed operation, and modular flexibility, this solution offers beverage manufacturers a reliable and efficient way to transport their products along the production line. Furthermore, with extensive support and service from {}, companies can trust that their conveyor systems will continue to meet their needs for years to come.

Company News & Blog

Revolutionary Gravity Spiral Conveyor: Advancing Material Handling Efficiency and Productivity

Gravity Spiral Conveyor Revolutionizes Material Handling[City Name], [Date] - With the constant advancements in technology, the field of material handling is undergoing a significant transformation. Companies are constantly seeking innovative solutions to streamline operations and enhance efficiency in the movement of goods. Introducing the revolutionary Gravity Spiral Conveyor, a game-changing invention that is set to redefine the way materials are transported.[Company Name], a renowned leader in manufacturing cutting-edge material handling systems, has brought forth this groundbreaking technology. With a vast experience in the industry, [Company Name] has always been at the forefront of developing solutions to overcome the challenges faced by businesses worldwide.The Gravity Spiral Conveyor is a state-of-the-art system that utilizes gravity and spiral movement to transport materials smoothly and rapidly. This innovative conveyor is capable of handling a wide range of products, including delicate items, packaged goods, and even bulk materials. The unique spiral design allows for gentle handling without compromising the speed and efficiency of material transfer.One of the key features of the Gravity Spiral Conveyor is its ability to operate at varying angles and inclinations. This flexibility makes it suitable for a diverse range of applications across multiple industries. Whether it is in the food and beverage sector, pharmaceuticals, automotive manufacturing, or logistics, this conveyor system can seamlessly integrate into existing production lines.Unlike traditional conveyors, which often require complex infrastructure and regular maintenance, the Gravity Spiral Conveyor is designed for simplicity and ease of use. Its compact design allows for efficient utilization of space, reducing the need for extensive modifications to existing facilities. The modular construction of the system facilitates quick installation, minimizing downtime and maximizing productivity.The Gravity Spiral Conveyor also boasts impressive load-carrying capabilities. With its robust construction and advanced engineering, it can handle heavy loads, making it ideal for demanding applications. The system is equipped with advanced safety features, including sensors and safety interlocks, ensuring the protection of both operators and the materials being transported.Furthermore, the Gravity Spiral Conveyor has integrated smart technology, enabling real-time monitoring and control. With the use of sensors and automation, companies can optimize their operations, reduce manual labor, and ensure continuous material flow. The ability to gather and analyze data provides valuable insights, allowing businesses to make data-driven decisions and enhance overall efficiency.In an era where sustainability and environmental consideration are paramount, the Gravity Spiral Conveyor stands out as an eco-friendly solution. By utilizing gravity as a driving force, energy consumption is significantly reduced compared to traditional conveyors. This not only helps companies minimize their carbon footprint but also results in cost savings in the long run.Customer satisfaction is one of the pillars of [Company Name]'s business philosophy. They offer comprehensive services, including installation, customization, and ongoing support. With a team of highly skilled engineers and a dedicated customer service department, businesses can rely on [Company Name] for seamless implementation and reliable after-sales assistance.The Gravity Spiral Conveyor has already gained recognition and praise from companies that have integrated it into their material handling operations. Its ability to improve efficiency, reduce manual labor, and enhance the overall flow of goods has proven to be a game-changer. With its unmatched versatility and technological superiority, the Gravity Spiral Conveyor is set to revolutionize the material handling industry.About [Company Name]:[Company Name] is a leading manufacturer of innovative material handling systems. With a commitment to excellence, they have continuously developed cutting-edge solutions that meet the dynamic needs of modern businesses. With a focus on efficiency, reliability, and customer satisfaction, [Company Name] has established itself as a trusted partner in the material handling industry.Contact Information:[Company Name]Address: [Address]Phone: [Phone Number]Email: [Email Address]Website: [Website URL]

Benefits of Using Corrugated Aluminium for Your Project

Corrugated Aluminium, the Future of Sustainable PackagingIn an era where sustainability is at the forefront of many industries, the demand for eco-friendly materials is steadily increasing. One such material that has gained traction in recent years is corrugated aluminium, a lightweight and durable material that is not only environmentally friendly but also offers numerous benefits for packaging applications.Corrugated aluminium is a versatile material that is highly regarded for its strength and resistance to corrosion, making it an ideal choice for packaging goods in various industries. The use of corrugated aluminium in packaging has increased in recent years, as companies seek to reduce their environmental footprint and meet consumer demands for sustainable products. With its exceptional strength-to-weight ratio, corrugated aluminium offers superior protection for goods during transportation, ensuring that products reach their destination in pristine condition.One company at the forefront of the corrugated aluminium industry is {Company Name}. With a strong focus on sustainability and innovation, {Company Name} has become a leading provider of corrugated aluminium packaging solutions, offering a wide range of products designed to meet the unique needs of their clients. From custom packaging design to mass production, {Company Name} is committed to delivering high-quality, environmentally friendly solutions that set the standard for the industry.Established in {year}, {Company Name} has quickly risen to prominence as a trusted supplier of corrugated aluminium packaging. Their commitment to sustainability is evident in their production processes, as they utilize advanced technologies to ensure that their products are both efficient and eco-friendly. Additionally, {Company Name} actively seeks to minimize their environmental impact by implementing sustainable practices throughout their operations.One of the many advantages of corrugated aluminium packaging is its recyclability. Unlike traditional packaging materials such as plastic or paper, corrugated aluminium is 100% recyclable, meaning that it can be used repeatedly without accumulating in landfills. This aligns with {Company Name}'s commitment to sustainability, as they strive to promote the use of recyclable materials within the packaging industry. By offering a recyclable alternative to traditional packaging materials, {Company Name} is helping their clients reduce their environmental footprint while maintaining the functionality and durability of their packaging solutions.{Company Name} also stands out for its dedication to innovation and customization. Their team of experienced engineers and designers work closely with clients to develop tailored corrugated aluminium packaging solutions that meet their specific needs. Whether it's for fragile electronic equipment, perishable goods, or heavy industrial equipment, {Company Name} has the expertise to create packaging that ensures the safe and secure transportation of valuable products.Furthermore, {Company Name} adheres to strict quality control measures to guarantee the reliability and consistency of their products. This commitment to excellence has earned them a reputation for delivering packaging solutions that exceed industry standards, further solidifying their position as a leader in the corrugated aluminium industry.As the demand for sustainable packaging continues to grow, {Company Name} is well-positioned to meet the needs of clients across various industries. With their unwavering dedication to sustainability, innovation, and quality, they are poised to drive the widespread adoption of corrugated aluminium as the future of sustainable packaging.In conclusion, the use of corrugated aluminium in packaging represents a significant step towards a more sustainable and environmentally conscious future. With companies like {Company Name} leading the way, the widespread adoption of corrugated aluminium packaging is poised to revolutionize the industry and pave the way for a more sustainable approach to packaging and transportation. As consumer demand for eco-friendly products continues to increase, it is clear that corrugated aluminium will play a key role in shaping the future of sustainable packaging.

Increase Efficiency with a High-Quality Conveyor System for Box Transportation

[Headline]Groundbreaking Conveyor System Revolutionizes Material Handling Processes[Subheading]Cutting-Edge Conveyor Solution Offers Enhanced Efficiency for Logistics and Warehousing Operations[Date]Month Day, Year[City, State]Location[Publication Name/Website]www.example.com[Byline]By [Author Name][Word Count]800 words---[Opening paragraph]Innovations in material handling have reached new heights with the introduction of a groundbreaking conveyor system that promises to revolutionize logistics and warehousing operations. The cutting-edge technology, developed by a leading industry player, eliminates manual labor while enhancing efficiency, making it a game-changer for businesses seeking to streamline their processes and increase productivity.[Company Introduction]With years of expertise in the field of material handling solutions, the company behind the groundbreaking conveyor system has established itself as a global leader in the industry. Their commitment to innovation and understanding of market demands has enabled them to develop this state-of-the-art solution that aims to transform the way logistics and warehousing operations function.[Background Information]The conventional manual handling of materials has long been a bottleneck in the supply chain industry, causing delays, errors, and inefficiencies. The introduction of the new conveyor system provides a solution to these challenges by automating the movement of goods. It encompasses advanced technologies such as computer vision, artificial intelligence, and robotics to create a highly efficient and adaptable system that can be easily integrated into existing workflows.[Benefits of the Conveyor System]1. Increased Efficiency: By eliminating the need for manual labor in material handling, the conveyor system significantly speeds up processes, reducing transit times and increasing the overall throughput of operations. This improvement in efficiency translates into cost savings and improved customer satisfaction.2. Error Reduction: Human errors in handling materials, such as misplacement or mislabeling, can lead to significant repercussions in logistics operations. The automated nature of the conveyor system minimizes such errors, ensuring accurate sorting, routing, and tracking of goods.3. Scalability: The conveyor system's modular design enables easy expansion and customization to handle diverse product types and volumes. Whether businesses deal with large or small items, the system can be configured to meet their specific requirements, allowing for seamless growth and adaptation.4. Enhanced Safety: With the elimination of manual labor in material handling, the risk of workplace injuries is greatly reduced. Employees can be reassigned to more value-added tasks, while the system guarantees the safe and careful movement of goods.5. Real-Time Insights: Through the integration of data analytics and advanced sensors, the conveyor system provides real-time insights into various aspects of material handling. This allows businesses to identify bottlenecks, monitor performance, and make data-driven decisions, leading to further process optimization and improved resource allocation.[Industry Impact]The introduction of this groundbreaking conveyor system has already garnered significant attention within the logistics and warehousing industry. Experts believe that its potential to enhance efficiency, reduce costs, and mitigate risks will rapidly transform the way businesses handle their supply chains. As companies seek to stay competitive in an increasingly fast-paced market, this innovative solution offers them the opportunity to streamline their operations and gain a competitive edge.[Closing]The material handling landscape is on the verge of a radical transformation, thanks to the recent introduction of a cutting-edge conveyor system developed by a leading industry player. By automating the movement of goods, increasing efficiency, reducing errors, and enhancing safety, this groundbreaking solution is set to revolutionize logistics and warehousing operations. As businesses strive to meet consumer demands while improving their bottom line, incorporating such advanced technologies is a crucial step towards success in the modern world of material handling.

The Cost of Spiral Conveyors: Unveiling the Price Factors

Spiral Conveyor Cost: An Insight into its Features and BenefitsIn today's dynamic and evolving world, businesses and manufacturers are continuously looking for ways to increase their productivity and efficiency while keeping costs low. One technology that has helped businesses achieve this is the spiral conveyor system, which provides a gradual elevation for products, without impacting their orientation. This article provides insights into Spiral Conveyor Cost, by delving into its features, benefits and company introduction.Spiral conveyors are one of the most effective types of conveying systems, particularly when it comes to the efficient movement of materials within a production facility. A spiral conveyor can handle a range of products, including containers, boxes, bags, and cartons, providing a reliable and safe method of transportation. Spiral conveyor systems are also highly customizable, allowing for businesses to adjust the systems to meet their specific needs.Spiral conveyor systems are highly effective in reducing space requirements, making them ideal for businesses with limited floor space. By taking up less floor space, the system saves on real estate costs, potentially lowering Spiral Conveyor Cost. Spiral conveyors can also be integrated into existing production lines, providing an effective solution for increasing the flow of materials.One of the most significant benefits of Spiral Conveyor Cost is its ability to increase productivity levels. Spiral conveyors provide an efficient and continuous flow of materials, reducing downtime for businesses. By minimizing the time products spend in transit, businesses can improve order fulfillment times, ultimately increasing customer satisfaction. As a result, businesses can also increase their revenue and profitability.Another benefit of Spiral Conveyor Cost is its versatility. Spiral conveyor systems can be used in a range of industries, including food processing, pharmaceutical, packaging, and manufacturing. As such, it is an excellent investment for businesses looking to increase efficiency and productivity, regardless of their industry.Companies looking to invest in a Spiral Conveyor system can turn to a trusted partner for help. A reliable and experienced provider of Spiral Conveyor systems can offer businesses with the best possible solution, meeting their specific needs. In addition, companies can opt for a provider that offers technical support and maintenance services, ensuring optimal system performance and longevity.Nest-Fill Machinery is one such provider, offering a range of Spiral Conveyor systems designed to meet the specific needs of different businesses. The company has adopted the latest technologies and innovative ideas to provide high-quality conveyor systems that come with a range of design and customization features, making them highly efficient and productive.Nest-Fill Machinery's Spiral Conveyor systems have been designed with efficiency in mind, relying on the most advanced software programs and expert engineers in their development. The systems are designed to achieve maximum efficiency and reliability, delivering optimal performance around the clock.In conclusion, Spiral Conveyor Cost is an excellent investment for businesses looking to improve efficiency, productivity, and profitability. The system is highly customizable, versatile, and efficient, providing a range of benefits that make it highly attractive for businesses across different industries. By investing in a Spiral Conveyor system, businesses can optimize their production process, meeting the demands of their customers and staying competitive in today's dynamic business environment. With reliable support from a trusted partner such as Nest-Fill Machinery, businesses can rest assured that they have made an investment that will provide a solid return on investment.

How Variable Speed Belts Improve Industrial Performance

Title: Innovative Variable Speed Belt Revolutionizes Industrial EfficiencyIntroduction:The ever-increasing demand for improved industrial efficiency and productivity has resulted in the introduction of various cutting-edge technologies and tools. One such groundbreaking solution is the state-of-the-art Variable Speed Belt, designed to optimize industrial operations and enhance overall performance. This innovative application, developed by an industry-leading company, promises to reshape the landscape of industrial automation.Overview of the Company:With a strong commitment to innovation and a track record of groundbreaking solutions, the company has established itself as a trusted name in the industrial automation sector. Holding expertise in developing cutting-edge technologies, the company has consistently pushed the boundaries of industrial efficiency since its inception. Headquartered in [Location], the company has a global presence, serving diverse industries ranging from manufacturing to logistics and everything in between.The Revolutionary Variable Speed Belt:The Variable Speed Belt is a game-changing product that incorporates advanced technology to improve efficiency and productivity in industrial operations. Designed by a team of highly skilled engineers, this belt offers myriad benefits and has the potential to transform the way industries operate.1. Unparalleled Flexibility and Adaptability:The Variable Speed Belt is renowned for its unparalleled flexibility, allowing it to seamlessly adjust its speed and adapt to varying operational requirements. By dynamically responding to changes in load and speed, this belt ensures optimal performance under different conditions, thereby maximizing productivity.2. Enhanced Energy Efficiency:With a focus on sustainability, the Variable Speed Belt reduces energy consumption by effectively utilizing power only when needed. By automatically adjusting the speed to match the requirements of the application, it minimizes energy wastage, leading to substantial cost savings and a reduced carbon footprint.3. Improved Operation Accuracy:Precision is a crucial aspect of industrial operations, and the Variable Speed Belt delivers just that. This belt eliminates inconsistencies caused by traditional fixed-speed belts by maintaining a consistent rotational speed, resulting in enhanced accuracy and superior product quality.4. Reduced Downtime and Maintenance Costs:The Variable Speed Belt boasts enhanced durability, reducing the frequency of maintenance downtime. This, in turn, improves overall operational efficiency and optimizes productivity. Combined with a longer service life and easy maintenance, industries can expect significant cost savings when adopting this innovative technology.5. Versatility Across Multiple Industries:The versatility of the Variable Speed Belt allows its application across a wide range of industries. From assembly lines in automotive manufacturing to material handling in logistics, this belt can adapt to the unique requirements of various industrial applications, making it a universally beneficial solution.In Conclusion:The introduction of the Variable Speed Belt represents a significant milestone in the evolution of industrial automation. With its numerous advantages, including unparalleled flexibility, enhanced energy efficiency, improved accuracy, reduced downtime, and versatility, this cutting-edge belt is bound to revolutionize industrial operations across the globe.As the global industry continues to strive for increased productivity, reduced costs, and improved sustainability, the Variable Speed Belt offers a comprehensive solution that ensures optimal performance while minimizing environmental impact. The company's commitment to delivering innovative solutions solidifies its position as an industry leader cementing its role in shaping the future of industrial automation.

Exploring the Benefits of Z Profile Steel for Structural Needs

Possible news article:New Z Profile Steel System Boosts Structural Efficiency and SustainabilityA leading manufacturer of steel solutions has launched an innovative Z profile steel system that promises to enhance the performance, durability, and environmental impact of a wide range of construction projects. The new technology, which is available in different sizes and shapes to meet various requirements, relies on a proprietary manufacturing process that reduces material waste and energy consumption while increasing precision and reliability.The company, which has a long history of expertise in steel production and design, developed the Z profile steel system in response to growing demand for more efficient and sustainable building solutions. The product combines several advanced features that optimize structural strength, flexibility, and ease of installation, as well as reduce the carbon footprint and life cycle cost of buildings. These features include:- A unique geometry that distributes loads more evenly and reduces stress concentration, thereby improving resistance to deformation and fatigue. The Z profile shape also allows for greater span-to-depth ratios, which can reduce the need for intermediate supports and enhance open-plan layouts and natural lighting.- A high-quality steel grade that provides superior mechanical properties and corrosion resistance, resulting in longer lifespan and lower maintenance costs. The steel is sourced from reputable suppliers and subjected to stringent tests and certifications to ensure compliance with international standards and regulations.- A patented forming process that minimizes waste material and energy consumption by up to 50%, compared to traditional rolling and cutting methods. The process involves cold-forming the steel coils into precise profiles without generating excessive heat or scrap, and then cutting them to length and punching holes for connections. This not only saves raw materials and electricity, but also reduces transportation, storage, and handling costs.- A comprehensive range of accessories and components that enable easy and secure assembly and installation of the Z profile steel system. These include nuts, bolts, washers, brackets, clamps, and end caps, as well as pre-drilled holes and chamfers that ensure accurate alignment and jointing. The system can be used for various applications, such as roofs, walls, floors, mezzanines, bridges, and towers, and can be adapted to different design styles and aesthetic preferences.A spokesperson for the company said that the Z profile steel system represented a major breakthrough in steel technology and sustainability, as it offered a holistic approach to building solutions that integrated structural, economic, and environmental aspects. "We believe that this technology can help architects, engineers, builders, and developers to create buildings that are not only functional and beautiful, but also resilient, efficient, and responsible," said the spokesperson. "With the Z profile steel system, we aim to contribute to the global efforts to mitigate climate change, promote circular economy, and enhance human well-being."The spokesperson also emphasized that the Z profile steel system was backed by a strong commitment to quality, service, and innovation, and that the company was dedicated to continuous improvement and customer satisfaction. "We have invested significant resources in research, development, and testing to ensure that our products and services meet and exceed the expectations of our customers and partners. We also offer technical support, training, and customization options to help our clients achieve their specific goals and challenges."The Z profile steel system is now available worldwide, through the company's network of distributors, agents, and partners. The company also has a website and social media channels that provide more information and resources on the benefits, features, and applications of the system.

Revolutionary Articulated Feet: the Future of Adaptive Footwear

Articulated Feet: Revolutionizing Mobility(Articulated Feet logo)Date: [Insert date]With the ongoing advancements in technology, the robotics industry is witnessing groundbreaking innovations that are redefining the way we live and work. One such innovation is the development of Articulated Feet – a revolutionary product that has the potential to transform the mobility landscape.Articulated Feet, developed by [Company Name], is a cutting-edge technology that offers a new level of versatility and adaptability for mobile robots. These feet are designed to closely mimic the functionality and motion of human legs, enabling enhanced stability and maneuverability in a variety of terrains and conditions. This breakthrough technology brings robots one step closer to replicating human-like movement, making them more useful in a wide range of applications.[Company Name] is a renowned pioneer in the field of robotics, specializing in the development of unique and innovative solutions that push the boundaries of what is possible. With an impressive track record of successful projects, [Company Name] has cemented its position as a trusted and reliable provider of cutting-edge robotics technology.The key features of Articulated Feet include advanced motion control, multi-axis articulation, and adaptability to different surfaces. These feet offer significant advantages over traditional solutions, enabling robots to navigate challenging environments with ease. The precise motion control allows for natural movements, enhancing stability and increasing the range of activities that robots can perform.The multi-axis articulation allows the feet to adapt to uneven or rough surfaces, paving the way for robotics applications in industries such as construction, agriculture, search and rescue, and exploration. By mimicking the human gait, robots equipped with Articulated Feet can traverse both indoor and outdoor environments without compromising on stability or performance.Additionally, Articulated Feet are designed to be easily integrated with a wide range of robotic platforms. This flexibility ensures that the technology can be seamlessly incorporated into existing robotic systems, saving time and resources for companies that wish to leverage this breakthrough innovation.One of the potential applications for Articulated Feet is in the field of disaster response and search and rescue operations. The ability of these feet to adapt to challenging terrains will enable robots to navigate rubble, debris, and other hazardous conditions with greater ease and efficiency. This can significantly improve the speed and effectiveness of search and rescue missions, ultimately saving more lives.Moreover, the agricultural industry can benefit immensely from Articulated Feet. Robots equipped with this technology can navigate uneven and unpredictable terrains such as fields, orchards, and vineyards. By doing so, they can automate tasks such as harvesting, spraying, and crop monitoring, leading to increased efficiency and reduced operational costs.Articulated Feet also have the potential to transform construction sites. By providing enhanced stability and maneuverability, robots with these feet can assist in tasks such as inspection, maintenance, and material transport. This not only increases productivity but also improves safety by reducing the need for human intervention in hazardous environments.In conclusion, Articulated Feet developed by [Company Name] offer a revolutionary and adaptable solution for mobile robots. Their ability to mimic human-like movements and adapt to various terrains sets a new standard for mobility in the robotics industry. With potential applications in disaster response, agriculture, construction, and numerous other industries, Articulated Feet are poised to bring about significant advancements in robotic technology. As [Company Name] continues to innovate, we can expect even more game-changing developments in the near future.

Revolutionary New Design of a Prosthetic Foot for Amputees

Articulated Foot Technology: Revolutionizing the Prosthetic IndustryWhen technology and innovation come together, it can help in overcoming major challenges and help in the development of life-changing products. The development of the Articulated Foot technology is a perfect example of technological innovation persisting to improve people's daily lives.The Articulated Foot is a revolutionary prosthetic that has been designed to provide users with an unparalleled level of comfort and control. In recent years, the prosthetics industry has evolved into a more advanced and personalized one. The introduction of this new technology has brought forth new hope for amputees and injured individuals, allowing for a more bespoke and flexible approach to prosthetic design.Articulated Foot the New Frontier in Prosthetic designIt all started when the founders noticed that the existing prosthetic foot designs were not fulfilling the real needs of amputees. So, they decided to merge their obsession for technology and biomechanics to create a prosthetic foot system that can cater to amputees' needs more efficiently and effectively. Thus, the Articulated Foot technology was created.The Articulated Foot technology is a breakthrough in prosthetic design that offers a natural and smooth walking experience for the user. Expertly crafted and designed with biomechanical precision, each foot system is made to match the individual's gait and offer great stability and protection.The foot system consists of a set of springs, which acts as the ankle and forefoot, along with the heel plate, which acts as the heel. The springs replicate the action of the ankle, which enables the foot system to store and release energy. The heel plate controls the motion and force underfoot, ensuring efficient energy transfer. These features make the Articulated Foot the most bio-mechanically advanced prosthetic foot system available.Articulated Foot - A game-changer in prosthetic IndustryIn the current scenario, the prosthetic industry has become more competitive than ever. With new and improved designs and materials emerging, consumers' demand for personalized solutions has risen. The Articulated Foot technology has taken the industry by storm by providing a level of comfort and control that far surpasses traditional prosthetic foot systems.The Articulated Foot technology is a game-changer in the prosthetic industry. With its advanced design and natural gait, it offers wearers a sense of confidence and independence that was once lost with the loss of a limb. This technology has also helped amputees return to their active lifestyles by improving their mobility and stability.Furthermore, the Articulated Foot technology is not only limited to lower limb prosthetics, but it also benefits individuals with upper limb loss. Upper limb prostheses are also a challenging area that requires a similar level of fine-tuning. Articulated Foot technology is equally applicable and successful in upper limb prostheses, providing users with improved functionality and mobility.Articulated foot technology has proven to be a significant milestone in the prosthetic industry. It has given a new lease of life to a significant portion of the population, helping them lead a more confident, independent, and active lifestyle.ConclusionThe Articulated Foot technology has proven how innovation and technology can transform lives and provide life-changing solutions, maximizing the user's comfort, mobility, and independence.This product offers a ray of hope for individuals with limb loss and has restored confidence in their lives. It portrays a great example of how technological advancements and innovations are setting the new benchmark for social and economic development.With technology and innovation continuing to evolve, the prosthetics industry is going to witness significant transformations in the future. The Articulated Foot technology is just the beginning, and with its ability to cater to individual needs and improve their quality of life, this technology will revolutionize the industry for years to come.

Innovative Food Packing Machine for Efficient Packaging Operations

[Company Name] Introduces State-of-the-Art Food Packing Machine[City, State, Date] - [Company Name], a leading provider of food packaging solutions, has recently unveiled its latest innovation in the form of a state-of-the-art food packing machine. This cutting-edge technology is set to revolutionize the food packaging industry by offering unparalleled efficiency, speed, and precision.The new food packing machine is equipped with advanced features that cater to the unique needs of food manufacturers and packagers. It is specially designed to handle a wide range of food products, including snacks, fruits, vegetables, and more, and can adapt to various packaging formats and materials.One of the key highlights of this new machine is its high-speed capabilities, allowing it to efficiently process large quantities of food products in a short amount of time. This will greatly enhance the productivity and output of food packaging operations, enabling businesses to meet the growing demands of the market.Furthermore, the machine is equipped with state-of-the-art sensors and controls that ensure the accuracy and consistency of the packaging process. This guarantees that products are packed in a precise and uniform manner, maintaining their quality and freshness throughout the packaging process.In line with [Company Name]'s commitment to sustainability, the food packing machine is designed to minimize food wastage and optimize packaging materials. It is equipped with smart technology that optimizes the use of packaging materials, reducing excess waste and lowering the overall environmental impact of the packaging process.The company's spokesperson, [Spokesperson's Name], expressed excitement about the launch of the new food packing machine, stating, "We are thrilled to introduce this cutting-edge technology to the market. Our team has worked tirelessly to develop a solution that meets the evolving needs of the food packaging industry, and we are confident that this machine will greatly benefit our customers."[Company Name] has a long-standing reputation for delivering high-quality packaging solutions to food manufacturers and packagers. With a commitment to innovation and customer satisfaction, the company has established itself as a trusted partner in the industry, providing comprehensive support and expertise to its clients.The introduction of the new food packing machine is a testament to [Company Name]'s dedication to pushing the boundaries of technology and providing solutions that address the challenges faced by the food packaging industry. By combining cutting-edge technology with a focus on sustainability and efficiency, the company aims to set new standards for food packaging operations.In conclusion, the unveiling of [Company Name]'s state-of-the-art food packing machine represents a significant milestone in the evolution of the food packaging industry. With its advanced features and capabilities, this innovative technology is poised to revolutionize the way food products are packaged, setting new benchmarks for efficiency, precision, and sustainability. As [Company Name] continues to lead the way in delivering groundbreaking packaging solutions, it is certain that the new food packing machine will be a game-changer for food manufacturers and packagers.

Efficient and Reliable Packing Machine for Butter

The demand for butter packing machines has been on the rise in recent years, as the food industry continues to grow and evolve. In response to this demand, a leading packaging machinery company has introduced a new and innovative butter packing machine to meet the needs of butter manufacturers and producers.This new butter packing machine, designed and manufactured by the company, is equipped with the latest technology and features to ensure efficient and high-quality packaging of butter products. With a focus on precision and reliability, the machine is able to handle a wide range of butter packaging requirements, including different packaging sizes and formats.One of the key features of the new butter packing machine is its flexibility and versatility. It is capable of accommodating various packaging materials, such as foil, plastic, or paper, and can handle different packaging styles, including tubs, blocks, or sticks. This flexibility allows butter manufacturers to meet the diverse needs of their customers and deliver their products in a variety of packaging options.In addition to its flexibility, the butter packing machine also offers high-speed packaging capabilities, helping manufacturers to increase their production output and meet tight deadlines. The machine is designed to minimize downtime and maximize efficiency, enabling butter producers to maintain a smooth and continuous packaging process.Furthermore, the butter packing machine is equipped with advanced control systems and automation technology, which allows for precise and accurate packaging. This not only ensures the consistency and quality of the packaged butter products but also reduces the risk of errors and wastage during the packaging process.As a leading packaging machinery company, the company is committed to delivering state-of-the-art solutions to its customers in the food industry. With a strong focus on research and development, the company continuously strives to innovate and improve its packaging machinery to meet the evolving needs of the market.The introduction of the new butter packing machine is a testament to the company's dedication to providing cutting-edge solutions for butter manufacturers and producers. By understanding the specific requirements of the food industry, the company has developed a machine that is tailored to meet the unique challenges of butter packaging, ensuring that its customers can achieve optimal efficiency and productivity in their operations.The company's expertise in the design and manufacturing of packaging machinery is backed by its years of experience and a team of highly skilled professionals. With a commitment to customer satisfaction and support, the company provides comprehensive after-sales services, including installation, training, and maintenance, to ensure that its customers can fully maximize the capabilities of the butter packing machine.In conclusion, the introduction of the new butter packing machine by the company represents a significant advancement in the packaging machinery industry. With its advanced technology, flexibility, and high-speed capabilities, the machine is set to revolutionize the way butter products are packaged, offering butter manufacturers and producers a competitive edge in the market. As the demand for quality and efficient packaging solutions continues to grow, the company remains at the forefront of delivering innovative and reliable machinery to meet the evolving needs of the food industry.