Revolutionary Multi Speed Belt Shakes Up the Industry

By:Admin

Company News & Blog

Latest Technology Innovation: High-Quality Robot Vacuum Cleaner That Makes Cleaning A Lot Easier

Title: Innovative Vacuum Technology Revolutionizes the Cleaning IndustryIntroduction:In a remarkable development for the cleaning industry, a cutting-edge vacuum technology has been introduced by a leading company, revolutionizing the way households and businesses maintain cleanliness. The vacuum, aptly called Vacuum Top, brings forth a new era of advanced cleaning capabilities, making it easier and more efficient than ever before to achieve pristine, dust-free spaces. With its state-of-the-art features, Vacuum Top is set to redefine the cleaning experience for users across the globe.Launching the Revolutionary Vacuum Top:Designed and developed by a pioneering company at the forefront of innovation, Vacuum Top represents a remarkable breakthrough in vacuum technology. Built on a foundation of extensive research and engineering expertise, the product showcases a myriad of features that make it stand out from ordinary vacuums in the market.Product highlights:1. Advanced Suction Power: Vacuum Top boasts unparalleled suction power, capable of thoroughly and effortlessly cleaning surfaces, carpets, and upholstery. Equipped with a powerful motor, this vacuum can effectively eliminate even the most stubborn dust particles, allergens, and pet hair, leaving your living space fresh and immaculate.2. HEPA Filtration System: One of the standout features of Vacuum Top is its high-performance HEPA (High-Efficiency Particulate Air) filtration system. This system captures and traps microscopic particles, allergens, and even harmful bacteria, ensuring cleaner air quality and promoting a healthier environment for both homes and offices.3. Intelligent Smart Sensor Technology: Vacuum Top incorporates state-of-the-art smart sensor technology, enabling it to automatically adjust its suction power depending on the type of surface it is cleaning. This ensures optimal performance, as the vacuum effortlessly transitions from hard floors to carpets, offering a seamless cleaning experience.4. User-Friendly Design: Designed with usability in mind, Vacuum Top prioritizes convenience and ease of use for its users. With its lightweight construction and ergonomic handle, maneuvering the vacuum around your home or office becomes a hassle-free task. Additionally, the vacuum's bagless design and easy-to-empty dust container eliminate the need for frequent bag changes, simplifying maintenance.Company Introduction:With a mission to elevate the cleaning experience, the company behind Vacuum Top is dedicated to developing cutting-edge solutions that meet the evolving needs of modern consumers. Drawing upon a team of skilled engineers and designers, the company continually pushes the boundaries of innovation to create products that enhance the comfort and well-being of its users.Firmly committed to environmental sustainability, the company ensures that Vacuum Top adheres to strict energy efficiency standards. By minimizing power consumption while maximizing performance, the vacuum not only saves consumers money but also reduces its overall impact on the environment.Expanding Market Footprint:Since its launch, Vacuum Top has received widespread acclaim and has been embraced by households and businesses alike. Customers have praised its exceptional performance, ease of use, and high durability, making it a preferred choice in the competitive vacuum market.Looking ahead, the company plans to expand its market presence, making Vacuum Top available to an even larger consumer base. With its focus on consistently improving product functionality and enhancing customer satisfaction, the company aims to solidify its position as an industry leader in the vacuum technology sector.Conclusion:The introduction of Vacuum Top revolutionizes the way we approach cleaning, combining powerful suction, advanced filtration systems, and intelligent technology to offer an unparalleled cleaning experience. As concerns about cleanliness and hygiene continue to grow globally, Vacuum Top stands as a symbol of innovation and effectiveness, contributing to maintaining cleaner and healthier living and working spaces.

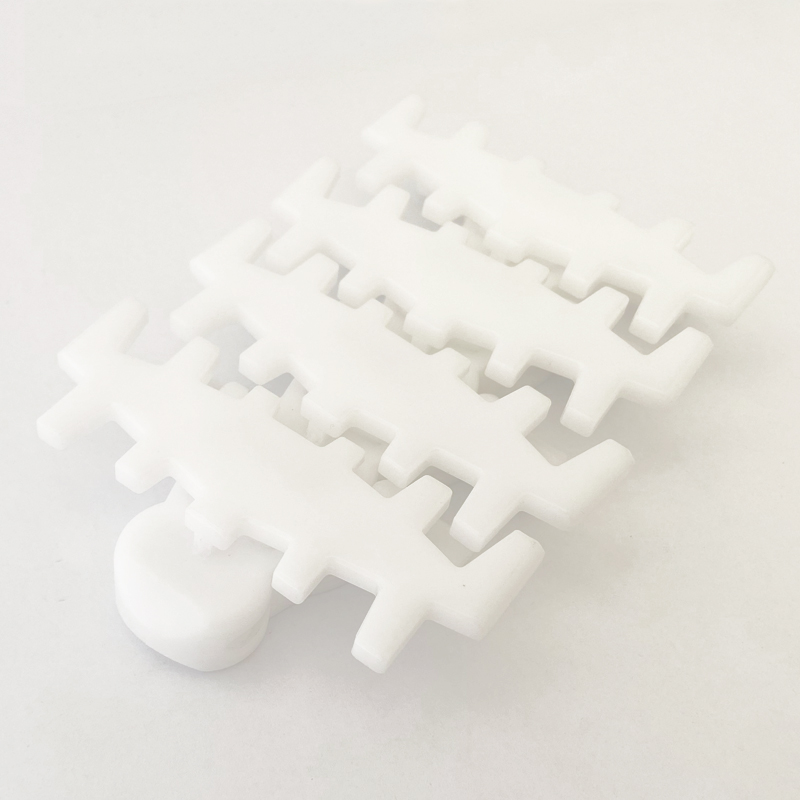

Conveyor System Benefits from Use of Plastic Belts

Plastic Belt Conveyor: A Revolutionary Innovation in the Conveyor IndustryThe conveyor industry has seen a tremendous shift in the last few decades. The increasing demand for automated material handling systems, the rise of the e-commerce industry, and a push towards sustainable solutions have all resulted in a surge of conveyor technology innovations.One such innovation that has taken the industry by storm is the Plastic Belt Conveyor. Introduced a few years ago, these conveyors have completely revolutionized automated material handling systems by providing faster, more sustainable and efficient transportation of goods across different industries.What is a Plastic Belt Conveyor?A Plastic Belt Conveyor is a revolutionary conveyor system that utilizes modular plastic belts to transport a variety of objects and materials. Unlike traditional conveyors that use a metal belt, plastic belts are lighter, stronger, and more durable, making them an excellent choice for high-speed, heavy-duty operations.Plastic Belt Conveyors are customizable to meet the unique requirements of various industries, including food processing, pharmaceuticals, packaging, and general manufacturing. The belts can be designed to handle a broad range of materials, from light to heavy-duty loads, and they are easy to clean, making them suitable for sanitary and sensitive environments.Features and Benefits of Plastic Belt Conveyors-Modular Design: Plastic Belt Conveyors feature a modular design that allows for easy assembly and disassembly. This feature makes assembly and maintenance a breeze and allows for flexibility where conveyor line configuration is concerned.-Low Maintenance Cost: Plastic Belt Conveyors have minimal maintenance requirements and can last longer than traditional metal belt conveyors. The belts need little to no lubrication and can be easily replaced when necessary.-Less Noise Pollution: Plastic belts are quieter than metal belts, reducing noise pollution in production environments.-Sustainable: Plastic Belt Conveyors are environmentally friendly, as they are made from recyclable materials and can be recycled at the end of their lifespan.-Easy to Clean: The ease of cleaning is one of the most notable features of Plastic Belt Conveyors. These conveyors can be cleaned thoroughly and efficiently, which is crucial in industries with stringent hygiene requirements like the food and pharmaceutical industries.The Company Introduction{name of the company} was established in 2005 and has become one of the leading manufacturers of Plastic Belt Conveyors. The company has its roots in the conveyor industry, with a wealth of experience in designing, manufacturing, and installing conveyor systems. We have earned a reputation for innovation, quality and reliability, which has seen us become the preferred partner of numerous companies across different industries.Our team of engineers is responsible for designing and producing the highest quality Plastic Belt Conveyors, using the latest technologies and manufacturing processes. Our products meet the requirements of various industries, from small companies to large-scale operations.Over the years, {name of the company} has developed a close-working relationship with our clients, understanding their needs, and providing tailored solutions that meet those needs. We guarantee our products, and our customer service is top-notch, which has earned us a reputation as a trusted and reliable partner among our clients.ConclusionThe Plastic Belt Conveyor has made a significant impact on the conveyor industry, providing a more efficient, sustainable, and customizable solution for material handling. Companies like {name of the company} have set the pace when it comes to designing and producing high-quality plastic belt conveyors that meet the increasing demands of different industries.As the conveyor industry continues to evolve, we can expect more innovations like the Plastic Belt Conveyor, which will continue to address the growing need for faster, safer, and more cost-efficient material handling systems in the manufacturing and distribution sector.

Plastic Square Pipe End Caps: A Convenient and Affordable Solution

Square Pipe End Cap Plastic: A Sustainable Solution for Industrial NeedsIn today's world, sustainability and environmental consciousness have become top priorities for every industry. The need to save resources and reduce waste has led to the development of various eco-friendly products and services. Square Pipe End Cap Plastic is one such innovative solution that is revolutionizing the industrial sector's approach towards sustainability.Square Pipe End Cap Plastic is a product manufactured by a leading company in the plastics industry. The product is designed to provide a secure and reliable protection solution to the exposed ends of square pipes. The end caps are made up of high-quality plastic that is recyclable, sturdy, and long-lasting. They come in various sizes to fit different pipe dimensions and can be customized as per the client's requirements.The Square Pipe End Cap Plastic is gaining popularity amongst industrial firms for its eco-friendliness and cost-effectiveness. Most industrial pipes are exposed to harsh environmental elements like chemicals, dust, and water, which can lead to corrosion and damage. This results in high maintenance costs and reduced pipe lifespan. End caps provide an affordable and sustainable solution to protect the pipes from such threats and increase their longevity.The end caps are also easily installable without the use of any advanced tools, making them extremely user-friendly. The plastic material is not affected by weather changes and does not deform, corrode, or rust over time, making them an ideal long-term solution. The easy availability of the product and its quick installation process saves industrial firms' time and money, while the product's eco-friendliness helps preserve the environment.The company manufacturing these end caps is also highly committed to sustainability and environmental protection. They have implemented various measures to reduce their carbon footprint and minimize waste. The company's production facilities operate with the latest technology and equipment that helps reduce energy consumption and wastage. They have also developed a comprehensive recycling program that encourages the responsible disposal of their products.The company's environmental commitment has not gone unnoticed, and they have received numerous awards and recognitions for their sustainable practices. Their products have been highly praised by industry experts, and their customers have expressed satisfaction with the quality and durability of the end caps.In conclusion, Square Pipe End Cap Plastic is an eco-friendly and sustainable solution for industrial firms looking to protect their pipes from damage and increase their lifespan. The product is user-friendly, cost-effective, and long-lasting, making it an ideal choice for businesses looking to reduce their maintenance costs. The company manufacturing these end caps has an unwavering commitment to sustainability and environmental protection, making them a responsible and reliable partner for any industry. As we move towards a more sustainable future, products like Square Pipe End Cap Plastic are leading the way in redefining the industrial sector's approach towards environmental responsibility.

Exploring the Benefits of Z Profile Steel for Structural Needs

Possible news article:New Z Profile Steel System Boosts Structural Efficiency and SustainabilityA leading manufacturer of steel solutions has launched an innovative Z profile steel system that promises to enhance the performance, durability, and environmental impact of a wide range of construction projects. The new technology, which is available in different sizes and shapes to meet various requirements, relies on a proprietary manufacturing process that reduces material waste and energy consumption while increasing precision and reliability.The company, which has a long history of expertise in steel production and design, developed the Z profile steel system in response to growing demand for more efficient and sustainable building solutions. The product combines several advanced features that optimize structural strength, flexibility, and ease of installation, as well as reduce the carbon footprint and life cycle cost of buildings. These features include:- A unique geometry that distributes loads more evenly and reduces stress concentration, thereby improving resistance to deformation and fatigue. The Z profile shape also allows for greater span-to-depth ratios, which can reduce the need for intermediate supports and enhance open-plan layouts and natural lighting.- A high-quality steel grade that provides superior mechanical properties and corrosion resistance, resulting in longer lifespan and lower maintenance costs. The steel is sourced from reputable suppliers and subjected to stringent tests and certifications to ensure compliance with international standards and regulations.- A patented forming process that minimizes waste material and energy consumption by up to 50%, compared to traditional rolling and cutting methods. The process involves cold-forming the steel coils into precise profiles without generating excessive heat or scrap, and then cutting them to length and punching holes for connections. This not only saves raw materials and electricity, but also reduces transportation, storage, and handling costs.- A comprehensive range of accessories and components that enable easy and secure assembly and installation of the Z profile steel system. These include nuts, bolts, washers, brackets, clamps, and end caps, as well as pre-drilled holes and chamfers that ensure accurate alignment and jointing. The system can be used for various applications, such as roofs, walls, floors, mezzanines, bridges, and towers, and can be adapted to different design styles and aesthetic preferences.A spokesperson for the company said that the Z profile steel system represented a major breakthrough in steel technology and sustainability, as it offered a holistic approach to building solutions that integrated structural, economic, and environmental aspects. "We believe that this technology can help architects, engineers, builders, and developers to create buildings that are not only functional and beautiful, but also resilient, efficient, and responsible," said the spokesperson. "With the Z profile steel system, we aim to contribute to the global efforts to mitigate climate change, promote circular economy, and enhance human well-being."The spokesperson also emphasized that the Z profile steel system was backed by a strong commitment to quality, service, and innovation, and that the company was dedicated to continuous improvement and customer satisfaction. "We have invested significant resources in research, development, and testing to ensure that our products and services meet and exceed the expectations of our customers and partners. We also offer technical support, training, and customization options to help our clients achieve their specific goals and challenges."The Z profile steel system is now available worldwide, through the company's network of distributors, agents, and partners. The company also has a website and social media channels that provide more information and resources on the benefits, features, and applications of the system.

How to Find Quality Wearstrips for Industrial Machinery

Title: Revolutionary Wearstrips Technology Set to Transform Various IndustriesIntroduction:In a groundbreaking development, an innovative wearstrips technology has been introduced by a leading company aiming to revolutionize different industries. With its exceptional durability and versatility, this cutting-edge solution is expected to transform the manufacturing, automotive, aerospace, and construction sectors. By addressing the challenges posed by wear and tear on various components, this revolutionary technology promises to enhance performance, extend the lifespan of equipment, and reduce maintenance costs. Company Introduction:{Company Name}, a pioneering force in technological advancements, has recently introduced a game-changing wearstrips technology that is set to disrupt multiple industries. With a mission to solve complex problems through innovation, {Company Name} focuses on developing sustainable and cost-effective solutions. Leveraging extensive research and expertise, the company aims to improve the efficiency and reliability of machinery, vehicles, and structures across various sectors, thereby enhancing overall productivity and safety.News Content:Paragraph 1: Introduction to Wearstrips TechnologyThe newly unveiled wearstrips technology is a breakthrough solution that provides enhanced protection against wear, corrosion, and other forms of damage on components. Manufactured using high-performance materials and state-of-the-art manufacturing processes, these wearstrips offer superior resistance to friction, impact, and environmental factors. Their versatile applications make them an invaluable resource across industries, enabling enhanced efficiency, reduced maintenance, and increased equipment lifespan.Paragraph 2: Manufacturing SectorIn the manufacturing sector, wearstrips technology plays a vital role in improving the performance of machinery and production equipment. By mitigating wear and tear on critical components, such as guide rails, conveyors, and bearings, manufacturers can significantly reduce downtime and minimize the need for costly repairs. The longevity of equipment ensures uninterrupted operations, enhancing productivity and optimizing output levels.Paragraph 3: Automotive SectorIn the automotive industry, wearstrips technology offers incredible benefits by protecting critical components against wear and damage caused by prolonged usage, road conditions, and external elements. These wearstrips can be applied to various parts, including brake pads, suspension systems, steering mechanisms, and engine components, resulting in increased safety, improved performance, and reduced maintenance costs. Ultimately, this innovation contributes to the longevity and reliability of vehicles.Paragraph 4: Aerospace SectorThe aerospace industry demands rigorous attention to detail and utmost reliability. Wearstrips technology provides a viable solution to minimize component wear, ensuring the safety and efficiency of aircraft. By applying wearstrips to critical parts like landing gear, engine components, and control surfaces, the risk of failure due to wear and tear is greatly reduced, contributing to enhanced flight safety. Moreover, these wearstrips offer resistance against extreme temperatures, humidity, and corrosion, thereby extending the service life of aerospace equipment.Paragraph 5: Construction SectorThe wear and tear experienced in the construction sector can have a significant impact on project timelines, efficiency, and budget. The integration of wearstrips technology in construction equipment and machinery offers a sustainable solution to minimize component damage and increase durability. From excavator teeth, bucket edges, and tracks to concrete forms, wearstrips ensure a longer lifespan for key equipment, reducing downtime and maintenance costs. This innovation empowers construction companies to execute projects more effectively and achieve greater profitability.Conclusion:The introduction of wearstrips technology by {Company Name} brings forth a pioneering solution to address wear and tear concerns across multiple industries. With its unparalleled durability, versatility, and resistance to various forms of damage, this innovative technology will undoubtedly redefine the manufacturing, automotive, aerospace, and construction sectors. By reducing maintenance requirements and enhancing the performance and longevity of critical components, wearstrips promise improved efficiency, safety, and cost-effectiveness for businesses operating in these sectors. It is clear that {Company Name} has taken a significant step towards driving innovation and sustainability in industries worldwide.

Durable Conveyor Belt for Heavy Duty Operations

article:Industrial sectors such as manufacturing, mining, and agriculture require heavy-duty conveyor belts to improve efficiency and productivity in their daily operations. {The Company}, a leading manufacturer of conveyor belts, has been producing high-quality and durable products that cater to the diverse needs of its customers for over a decade. This article will dive into their key strengths and capabilities, products and solutions, and future outlook.Key Strengths and Capabilities:{The Company} is a well-established and reputable brand that has gained immense popularity among its clients for its superior quality products. With its state-of-the-art manufacturing facilities, advanced technologies, and efficient workforce, the company has established itself as a market leader in the conveyor belt industry.The company is committed to providing excellent customer service and support, which has helped the company build lasting relationships with its customers worldwide. In addition, {The company} has a team of highly experienced engineers and technicians who provide customized solutions to their clients based on their specific needs.Products and Solutions:{The Company} produces a wide range of conveyor belts that cater to different industries such as mining, agriculture, manufacturing, and logistics. The company's products ensure efficient material handling, high durability, and minimum downtime, providing maximum productivity and profitability to its customers.{The Company} produces four types of conveyor belts: Steel Cord Conveyor Belts, Multi-ply Fabric Conveyor Belts, PVC Conveyor Belts, and Solid Woven Conveyor Belts. Each conveyor belt type has its unique features and benefits.For example, steel cord conveyor belts are suitable for high-tension applications such as long-distance underground mining, while multi-ply fabric belts are ideal for general-purpose applications such as transport of bulk materials on inclined surfaces.Similarly, PVC conveyor belts are ideal for light-duty applications such as food and beverage processing, while solid woven conveyor belts are perfect for use in harsh environments where resistance to chemicals and abrasion is a must.Future Outlook:{The Company} has a strong commitment to innovation and sustainability. The company invests heavily in research and development to enhance the performance and lifespan of its products continually. Furthermore, {The Company} has set ambitious goals to reduce its carbon footprint and ensure sustainable practices in its operations.The company is continuously expanding its global presence by establishing new partnerships and distribution channels. Currently, {The Company} has a presence in over 50 countries, and this number is likely to increase in the future.In conclusion, {The Company} has emerged as a leader in the conveyor belt industry through its commitment to quality, customer service, and innovation. With a wide range of conveyor belts that cater to diverse industries and a strong focus on sustainability, the company is well-positioned to grow and expand its operations in the future.

Revolutionary Swivel Head Technology Takes the World by Storm

Swivel Head, a leading manufacturer of innovative and reliable industrial machinery, continues to revolutionize the manufacturing industry with its cutting-edge technology. With a strong commitment to quality, efficiency, and customer satisfaction, the company has established itself as a trusted provider of solutions for various industrial sectors.Founded in the late 1990s, Swivel Head has been at the forefront of the industry, paving the way for advancements in productivity and precision. Its relentless pursuit of excellence and continuous innovation has earned the company a reputation for creating products that meet the evolving needs of its customers.Swivel Head offers a wide range of machinery, including CNC machines, robotic arms, and automated systems. These state-of-the-art tools are designed to streamline production processes, increase output, and reduce costs. The company's team of engineers and researchers works tirelessly to develop new technologies that push the boundaries of what is possible in the manufacturing world.One of Swivel Head's standout offerings is its line of CNC machines, known for their exceptional accuracy and reliability. These machines utilize computer numerical control technology to automate tasks that were once performed manually, resulting in significant time and cost savings. Additionally, the precise cutting and shaping capabilities of these machines ensure consistently high-quality products.Swivel Head also specializes in the development of robotic arms that can handle complex tasks with precision and efficiency. These automated systems are ideal for applications that require repetitive movements or intricate assembly processes. By incorporating intelligent algorithms and sensors, Swivel Head's robotic arms can adapt to changes in their environment and collaborate seamlessly with human workers.In recent years, Swivel Head has made great strides in the field of automation. Its cutting-edge AI-powered systems and internet of things (IoT) technology have transformed traditional manufacturing processes. By collecting and analyzing vast amounts of data in real-time, Swivel Head's smart machines can optimize production schedules, detect potential issues before they arise, and maximize overall efficiency.The company's commitment to customer satisfaction sets it apart from its competitors. Swivel Head takes a personalized approach when working with clients, carefully assessing their unique needs and challenges. Its team of experts collaborates closely with customers to develop tailored solutions that meet their specific requirements. From initial consultation to after-sales support, Swivel Head ensures that its clients receive the highest level of service and assistance.With a global footprint and a strong network of partners, Swivel Head has successfully implemented its solutions in various industries, including automotive, aerospace, electronics, and more. Its cutting-edge technology has proven to be instrumental in boosting productivity, minimizing downtime, and enhancing overall operational efficiency for its customers.As Swivel Head continues to innovate and expand its product range, it remains firmly committed to sustainability and environmental responsibility. The company actively seeks ways to reduce energy consumption and waste generation throughout its manufacturing processes. By incorporating eco-friendly materials and implementing energy-efficient technologies, Swivel Head strives to leave a positive impact on the planet.In conclusion, Swivel Head's dedication to innovation, quality, and customer satisfaction has solidified its position as a leader in the manufacturing industry. Its cutting-edge machinery and advanced technologies have transformed the way products are made, enabling companies to achieve higher productivity, precision, and profitability. As Swivel Head continues to push the boundaries of what is possible in manufacturing, it remains a trusted partner for businesses seeking to stay ahead in an increasingly competitive market.

Experts Reveal the Benefits of Using a Plastic Chains Conveyor Belt for Efficient Material Handling

Plastic Chains Conveyor Belt Boosts Efficiency and Sustainability in ManufacturingIn the ever-evolving manufacturing industry, advancements in technology and materials have significantly impacted productivity and sustainability. Among these innovations is the plastic chains conveyor belt, a highly efficient and environmentally-friendly solution that revolutionizes the way goods are transported within production facilities.Plastic chains conveyor belts, also known as modular belts, have gained popularity in recent years due to their versatility, durability, and ability to withstand heavy loads. Unlike traditional conveyor belts made of fabric or rubber, these belts consist of interconnected plastic modules that form a continuous surface. This modular design offers several advantages, such as increased flexibility, reduced downtime, and easy maintenance.One notable aspect of plastic chains conveyor belts is their ability to handle a wide range of product shapes and sizes, including irregular and heavy items. The interlocking modules ensure that products can be transported smoothly and securely, eliminating the risk of jams or blockages. This versatility makes these belts suitable for various industries, including automotive, food processing, pharmaceuticals, and logistics.The seamless design of plastic chains conveyor belts contributes to enhanced efficiency and operational productivity. The absence of hinges or joints minimizes the risk of wear and tear, thereby reducing the need for replacements or repairs. Furthermore, the belts can be easily customized to fit specific manufacturing requirements, allowing for seamless integration into existing production lines.Manufacturers can also enjoy significant energy savings by utilizing plastic chains conveyor belts. Compared to traditional belts with higher friction levels, these belts have lower energy consumption due to their smooth, low-friction surfaces. As a result, energy costs are reduced, contributing to overall cost savings and improved environmental sustainability.Sustainability has emerged as a key focus area for modern industries, and plastic chains conveyor belts align with this trend. The materials used in manufacturing these belts are typically recyclable or made from recycled materials, reducing their environmental impact. Additionally, the longer lifespan of these belts compared to traditional options further enhances their sustainability credentials.One company at the forefront of plastic chains conveyor belt innovation is {}. With a deep understanding of the manufacturing industry's needs, they have developed a range of high-quality belts that excel in performance and durability. Their belts undergo rigorous testing to ensure they meet industry standards and customer expectations. Moreover, {} offers extensive customer support, including installation guidance, maintenance recommendations, and after-sales service.In addition to their standard product offerings, {} specializes in customizable solutions tailored to specific manufacturing processes. Whether it is handling delicate components, heavy loads, or products with unique shapes, they can design and manufacture belts to effectively meet the requirements of any industry.Furthermore, {} actively promotes sustainability by incorporating eco-friendly practices in their manufacturing processes. They prioritize the use of recycled materials when possible and strive to minimize waste generation throughout their production cycle. By prioritizing eco-conscious solutions, {} is not only contributing to a greener environment but also providing their customers with options that align with their sustainability goals.The plastic chains conveyor belt is a game-changer in the manufacturing industry, offering increased efficiency, flexibility, and sustainability. With {} leading the way in innovation and customer-centric solutions, manufacturers can confidently adopt these belts and streamline their operations. As the industry continues to evolve, the plastic chains conveyor belt is poised to play a vital role in shaping the future of manufacturing.

Revolutionary Gravity Spiral Conveyor: Advancing Material Handling Efficiency and Productivity

Gravity Spiral Conveyor Revolutionizes Material Handling[City Name], [Date] - With the constant advancements in technology, the field of material handling is undergoing a significant transformation. Companies are constantly seeking innovative solutions to streamline operations and enhance efficiency in the movement of goods. Introducing the revolutionary Gravity Spiral Conveyor, a game-changing invention that is set to redefine the way materials are transported.[Company Name], a renowned leader in manufacturing cutting-edge material handling systems, has brought forth this groundbreaking technology. With a vast experience in the industry, [Company Name] has always been at the forefront of developing solutions to overcome the challenges faced by businesses worldwide.The Gravity Spiral Conveyor is a state-of-the-art system that utilizes gravity and spiral movement to transport materials smoothly and rapidly. This innovative conveyor is capable of handling a wide range of products, including delicate items, packaged goods, and even bulk materials. The unique spiral design allows for gentle handling without compromising the speed and efficiency of material transfer.One of the key features of the Gravity Spiral Conveyor is its ability to operate at varying angles and inclinations. This flexibility makes it suitable for a diverse range of applications across multiple industries. Whether it is in the food and beverage sector, pharmaceuticals, automotive manufacturing, or logistics, this conveyor system can seamlessly integrate into existing production lines.Unlike traditional conveyors, which often require complex infrastructure and regular maintenance, the Gravity Spiral Conveyor is designed for simplicity and ease of use. Its compact design allows for efficient utilization of space, reducing the need for extensive modifications to existing facilities. The modular construction of the system facilitates quick installation, minimizing downtime and maximizing productivity.The Gravity Spiral Conveyor also boasts impressive load-carrying capabilities. With its robust construction and advanced engineering, it can handle heavy loads, making it ideal for demanding applications. The system is equipped with advanced safety features, including sensors and safety interlocks, ensuring the protection of both operators and the materials being transported.Furthermore, the Gravity Spiral Conveyor has integrated smart technology, enabling real-time monitoring and control. With the use of sensors and automation, companies can optimize their operations, reduce manual labor, and ensure continuous material flow. The ability to gather and analyze data provides valuable insights, allowing businesses to make data-driven decisions and enhance overall efficiency.In an era where sustainability and environmental consideration are paramount, the Gravity Spiral Conveyor stands out as an eco-friendly solution. By utilizing gravity as a driving force, energy consumption is significantly reduced compared to traditional conveyors. This not only helps companies minimize their carbon footprint but also results in cost savings in the long run.Customer satisfaction is one of the pillars of [Company Name]'s business philosophy. They offer comprehensive services, including installation, customization, and ongoing support. With a team of highly skilled engineers and a dedicated customer service department, businesses can rely on [Company Name] for seamless implementation and reliable after-sales assistance.The Gravity Spiral Conveyor has already gained recognition and praise from companies that have integrated it into their material handling operations. Its ability to improve efficiency, reduce manual labor, and enhance the overall flow of goods has proven to be a game-changer. With its unmatched versatility and technological superiority, the Gravity Spiral Conveyor is set to revolutionize the material handling industry.About [Company Name]:[Company Name] is a leading manufacturer of innovative material handling systems. With a commitment to excellence, they have continuously developed cutting-edge solutions that meet the dynamic needs of modern businesses. With a focus on efficiency, reliability, and customer satisfaction, [Company Name] has established itself as a trusted partner in the material handling industry.Contact Information:[Company Name]Address: [Address]Phone: [Phone Number]Email: [Email Address]Website: [Website URL]