Innovative Pickle Packaging Machine for Efficient Food Processing

By:Admin

The Pickle Packing Machine comes equipped with a range of cutting-edge technologies that set it apart from conventional packaging machines. Its automated operation and high-speed packaging capabilities enable pickling companies to significantly increase their production output while maintaining consistent product quality. Moreover, the machine's flexibility allows for customization of packaging formats, catering to the diverse needs of pickled products in the market.

One of the key features of the Pickle Packing Machine is its ability to handle a wide variety of packaging materials, including glass jars, plastic containers, and pouches. This versatility makes it suitable for packaging various pickled products such as cucumbers, olives, peppers, and more. The machine's adjustable filling system ensures accurate and precise filling of the packaging, minimizing product wastage and ensuring cost efficiency for pickling companies.

In addition to its cutting-edge technology, the Pickle Packing Machine also prioritizes hygiene and food safety. It is designed with easy-to-clean components and meets the highest standards of sanitation, making it ideal for packaging food products. This feature is crucial for pickling companies to maintain the integrity and safety of their pickled products throughout the packaging process.

CEO of XYZ Company, Mr. John Smith, expressed his excitement about the new Pickle Packing Machine, stating, "We are proud to introduce this innovative packaging solution to the pickling industry. Our goal is to provide pickling companies with a reliable and efficient packaging machine that enhances their production capabilities and product quality. The Pickle Packing Machine is the result of extensive research and development, and we believe it will make a significant impact on the pickling industry."

Mr. Smith further emphasized the company's commitment to delivering high-quality packaging machinery that meets the evolving needs of food processing industries. With a strong focus on technological innovation and customer satisfaction, XYZ Company aims to continue developing cutting-edge packaging solutions for various food products, including pickled products.

The launch of the Pickle Packing Machine has already garnered significant interest from pickling companies worldwide. Several industry players have expressed their anticipation for the machine's potential to improve their packaging processes and drive operational efficiency. With its advanced technology and performance capabilities, the Pickle Packing Machine is poised to become the preferred choice for pickling companies looking to elevate their packaging operations.

As the pickling industry continues to grow and evolve, the demand for efficient and reliable packaging solutions is more crucial than ever. The introduction of XYZ Company's Pickle Packing Machine signifies a significant advancement in meeting this demand, offering pickling companies a competitive edge in the market.

In conclusion, XYZ Company's innovative Pickle Packing Machine is set to transform the pickling industry by providing a cutting-edge packaging solution that enhances efficiency, product quality, and food safety. With its advanced technology and commitment to meeting the specific needs of pickled products, the machine is poised to become a game-changer for pickling companies worldwide. As XYZ Company continues to drive innovation in the packaging machinery sector, the Pickle Packing Machine stands as a testament to their dedication to delivering industry-leading solutions for food processing industries.

Company News & Blog

Discover the Advantages of Plastic Modular Belts for Various Industries

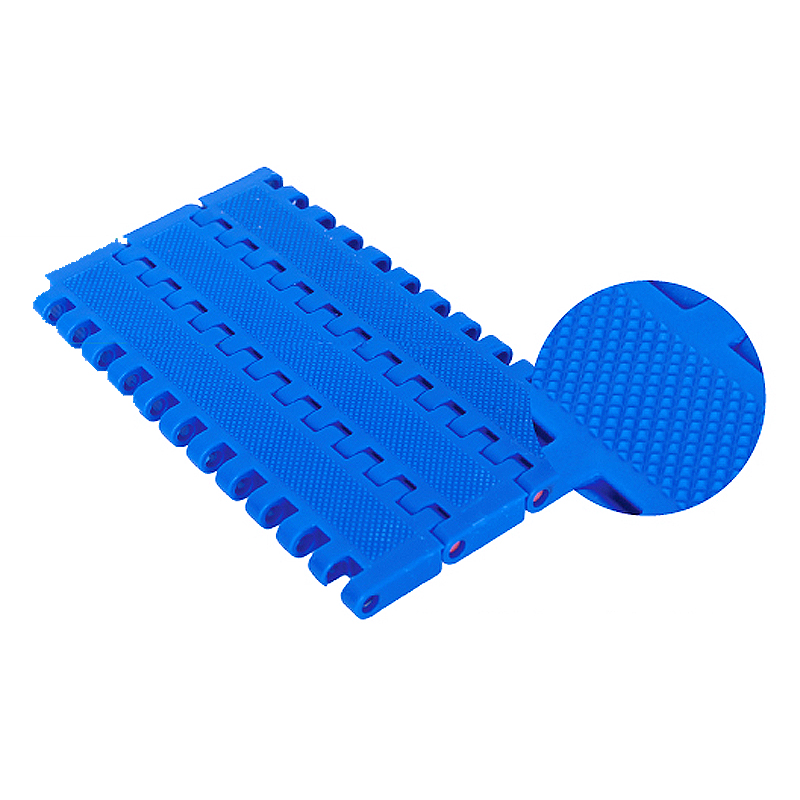

Plastic Modular Belt Company Leads Innovation in Conveyor Belt IndustryIn the world of conveyor belt technology, innovation and quality are crucial in meeting the demands of various industries. One company, known for its expertise in providing top-quality plastic modular belt solutions, is leading the way in revolutionizing the conveyor belt industry.Founded in the early 1990s, the company has been at the forefront of developing and manufacturing plastic modular belt systems that are used in a wide range of industries such as food processing, packaging, automotive, and logistics. The company's commitment to innovation, quality, and customer satisfaction has led to its position as a leading supplier of plastic modular belt solutions globally.The company's success can be attributed to its continuous investment in research and development, as well as its focus on understanding and meeting the specific needs of its customers. This commitment has led to the development of a wide range of plastic modular belt products that are designed to meet the highest standards of performance, durability, and reliability.One of the company's flagship products is the plastic modular belt, which has gained a strong reputation for its superior quality and innovative design. These belts are manufactured using high-quality materials and cutting-edge technology, ensuring that they can withstand the demanding conditions of industrial applications. The belts are designed with precision to ensure smooth and efficient operation, reducing downtime and maintenance costs for the end-users.In addition to the standard plastic modular belt solutions, the company also offers customized belt designs to meet the specific requirements of its customers. Whether it is a unique belt size, surface pattern, or material composition, the company's engineering team works closely with customers to develop tailored solutions that optimize their operations and maximize productivity.Furthermore, the company's commitment to sustainability and environmental responsibility is evident in its development of eco-friendly plastic modular belt solutions. These belts are designed to reduce energy consumption, minimize noise levels, and enhance the overall efficiency of conveyor systems, aligning with the global trend towards sustainable manufacturing practices.The company's dedication to quality and customer satisfaction is further reflected in its comprehensive after-sales support and service network. With a team of experienced technicians, the company offers timely maintenance, repair, and technical assistance to ensure that the plastic modular belt systems continue to perform at their best.As the demand for efficient and reliable conveyor belt solutions continues to grow, the company remains focused on driving innovation and exceeding customer expectations. With a strong emphasis on research and development, the company is continually exploring new technologies and materials to further enhance the performance and lifespan of its plastic modular belt products.Looking ahead, the company is poised to expand its global presence and solidify its position as the preferred supplier of plastic modular belt solutions. With a strong commitment to quality, innovation, and customer satisfaction, the company is well-positioned to lead the way in shaping the future of the conveyor belt industry.In conclusion, the company is at the forefront of innovation in the conveyor belt industry, offering top-quality plastic modular belt solutions that meet the diverse needs of various industries. With a strong focus on research and development, as well as a dedication to sustainability and customer satisfaction, the company is set to continue its leadership in driving the evolution of conveyor belt technology.

Experts recommend adhering to the standard belt loop width for optimal fit and style

Title: Standard Belt Loop Width Redefines Style and Diversifies Fashion ChoicesIntroduction:In an ever-evolving world of fashion, where trends change by the hour, some aspects remain rooted in tradition. One such key element is the belt loop, an understated yet essential component of any pair of trousers or jeans. A standard belt loop width not only ensures functionality but also plays a significant role in defining style and offering endless fashion choices. As diverse as the fashion industry itself, these belt loops have become the canvas upon which individuals can express their personality and showcase their unique style.Body:1. The Importance of Belt Loops: Belts have long been a fundamental accessory, serving the dual purpose of holding trousers in place and enhancing an outfit's overall look. However, it is the humble belt loop that ensures belts stay secure and properly positioned, while adding a touch of practicality and elegance. The standard belt loop width varies across different fashion brands; establishing this standard width ensures uniformity and compatibility.2. Versatility Across Various Fashion Styles: From classic to contemporary, streetwear to formal wear, belt loops are found in every wardrobe, resonating with a diverse range of fashion choices. Be it the subtle loops of a tailored suit or the flashy loops of a high-street denim brand, standardizing the belt loop width allows for seamless integration across different fashion styles, ensuring a cohesive and refined look.3. The Impact of Brand Innovation: Several fashion brands have taken the concept of belt loops to new creative heights, revolutionizing how they add character to clothing. Protruding loops, colored loops, or loops with unique embellishments have become increasingly popular, enabling individuals to experiment and make a statement with their fashion choices. By adhering to a standard belt loop width, such innovations can flourish, granting consumers endless options to express their personal style.4. Embracing Sustainability: As the world becomes more conscious of the environmental impact of the fashion industry, the focus on sustainable practices has grown. Standardizing belt loop width promotes eco-friendly practices as it allows for easy interchangeability and repair of belts and loops. By reducing waste and encouraging the reuse of accessories, consumers can make fashion choices that are both stylish and environmentally responsible.5. Customization and Personalization: Within the world of fashion, the ability to customize and personalize clothing is highly sought after. The standard belt loop width allows individuals to experiment with different belt materials, colors, and textures, elevating the overall look of an outfit. Ultimately, this facilitates self-expression and showcases individuality, giving fashion enthusiasts the freedom to curate unique styles tailored to their tastes.6. Ensuring Functionality and Durability: While fashion serves as a medium of personal expression, practicality should not be overlooked. A standard belt loop width ensures that belts hold securely and perform their intended function effectively. By adhering to set measurements, fashion companies prioritize durability and create high-quality products that are built to last.Conclusion:Fashion trends come and go, but certain elements like the standard belt loop width stand the test of time. By providing a foundation upon which various styles can flourish, belt loops have become more than just functional accessories; they are an intrinsic part of the fashion landscape. Whether adhering to classic designs or embracing contemporary innovations, the versatility and adaptability of standardized belt loops provide limitless options for individuals to express their unique style and elevate their fashion choices. So, next time you fasten your belt, take a moment to appreciate the simplicity and significance of those looped threads that adorn your waistband.

How to Find Quality Wearstrips for Industrial Machinery

Title: Revolutionary Wearstrips Technology Set to Transform Various IndustriesIntroduction:In a groundbreaking development, an innovative wearstrips technology has been introduced by a leading company aiming to revolutionize different industries. With its exceptional durability and versatility, this cutting-edge solution is expected to transform the manufacturing, automotive, aerospace, and construction sectors. By addressing the challenges posed by wear and tear on various components, this revolutionary technology promises to enhance performance, extend the lifespan of equipment, and reduce maintenance costs. Company Introduction:{Company Name}, a pioneering force in technological advancements, has recently introduced a game-changing wearstrips technology that is set to disrupt multiple industries. With a mission to solve complex problems through innovation, {Company Name} focuses on developing sustainable and cost-effective solutions. Leveraging extensive research and expertise, the company aims to improve the efficiency and reliability of machinery, vehicles, and structures across various sectors, thereby enhancing overall productivity and safety.News Content:Paragraph 1: Introduction to Wearstrips TechnologyThe newly unveiled wearstrips technology is a breakthrough solution that provides enhanced protection against wear, corrosion, and other forms of damage on components. Manufactured using high-performance materials and state-of-the-art manufacturing processes, these wearstrips offer superior resistance to friction, impact, and environmental factors. Their versatile applications make them an invaluable resource across industries, enabling enhanced efficiency, reduced maintenance, and increased equipment lifespan.Paragraph 2: Manufacturing SectorIn the manufacturing sector, wearstrips technology plays a vital role in improving the performance of machinery and production equipment. By mitigating wear and tear on critical components, such as guide rails, conveyors, and bearings, manufacturers can significantly reduce downtime and minimize the need for costly repairs. The longevity of equipment ensures uninterrupted operations, enhancing productivity and optimizing output levels.Paragraph 3: Automotive SectorIn the automotive industry, wearstrips technology offers incredible benefits by protecting critical components against wear and damage caused by prolonged usage, road conditions, and external elements. These wearstrips can be applied to various parts, including brake pads, suspension systems, steering mechanisms, and engine components, resulting in increased safety, improved performance, and reduced maintenance costs. Ultimately, this innovation contributes to the longevity and reliability of vehicles.Paragraph 4: Aerospace SectorThe aerospace industry demands rigorous attention to detail and utmost reliability. Wearstrips technology provides a viable solution to minimize component wear, ensuring the safety and efficiency of aircraft. By applying wearstrips to critical parts like landing gear, engine components, and control surfaces, the risk of failure due to wear and tear is greatly reduced, contributing to enhanced flight safety. Moreover, these wearstrips offer resistance against extreme temperatures, humidity, and corrosion, thereby extending the service life of aerospace equipment.Paragraph 5: Construction SectorThe wear and tear experienced in the construction sector can have a significant impact on project timelines, efficiency, and budget. The integration of wearstrips technology in construction equipment and machinery offers a sustainable solution to minimize component damage and increase durability. From excavator teeth, bucket edges, and tracks to concrete forms, wearstrips ensure a longer lifespan for key equipment, reducing downtime and maintenance costs. This innovation empowers construction companies to execute projects more effectively and achieve greater profitability.Conclusion:The introduction of wearstrips technology by {Company Name} brings forth a pioneering solution to address wear and tear concerns across multiple industries. With its unparalleled durability, versatility, and resistance to various forms of damage, this innovative technology will undoubtedly redefine the manufacturing, automotive, aerospace, and construction sectors. By reducing maintenance requirements and enhancing the performance and longevity of critical components, wearstrips promise improved efficiency, safety, and cost-effectiveness for businesses operating in these sectors. It is clear that {Company Name} has taken a significant step towards driving innovation and sustainability in industries worldwide.

What Is the Standard Conveyor Speed?

Standard Conveyor Speed Sets New Industry Standard for Efficiency and ReliabilityConveyor systems are an essential component of many industries, serving as the backbone of material handling operations. With the increasing demand for higher efficiency and reliability, companies are constantly seeking innovative solutions to improve their conveyor systems. It is in this context that Standard Conveyor Speed, a leading provider of conveyor solutions, has emerged as a trailblazer in the industry. With their unwavering commitment to excellence and cutting-edge technology, Standard Conveyor Speed has set a new industry standard for efficiency and reliability.Founded in 1990, Standard Conveyor Speed has built a reputation for delivering high-quality conveyor systems that enhance productivity and streamline operations. The company's vast experience and expertise in the field have enabled them to develop innovative solutions that cater to the diverse needs of their clients across various industries.One of the key factors that sets Standard Conveyor Speed apart from its competitors is its focus on research and development. The company has a dedicated team of engineers and designers who are constantly pushing the boundaries of conveyor technology to develop state-of-the-art solutions. This relentless pursuit of innovation has led to the creation of conveyor systems that offer unparalleled efficiency and reliability.One of the flagship products of Standard Conveyor Speed is their high-speed conveyor system, which has been hailed as a game-changer in the industry. This cutting-edge system is designed to handle the rigors of high-speed operations without compromising on safety or reliability. By leveraging advanced engineering and precision manufacturing, Standard Conveyor Speed has been able to deliver a conveyor system that meets the demands of modern manufacturing and distribution facilities.In addition to their high-speed conveyor system, Standard Conveyor Speed also offers a wide range of other conveyor solutions, including gravity conveyors, belt conveyors, and roller conveyors. Each of these systems is engineered to deliver optimum performance and durability, making them an ideal choice for companies looking to upgrade their material handling operations.Furthermore, Standard Conveyor Speed takes pride in its commitment to customer satisfaction. The company works closely with its clients to understand their specific requirements and then customizes solutions to meet their needs. This customer-centric approach has earned Standard Conveyor Speed a loyal client base who continue to rely on their expertise for their conveyor system needs.With an eye on sustainability, Standard Conveyor Speed also offers eco-friendly conveyor solutions that help companies reduce their carbon footprint. By integrating energy-efficient components and optimizing the design of their conveyor systems, Standard Conveyor Speed is playing a pivotal role in promoting sustainable practices in the industry.As a testament to the quality of their products and services, Standard Conveyor Speed has earned numerous accolades and certifications. The company's relentless pursuit of excellence has also been recognized by industry experts, further solidifying their position as a leader in the field.Looking ahead, Standard Conveyor Speed is dedicated to continuing its legacy of innovation and excellence. The company remains committed to staying at the forefront of conveyor technology, constantly iterating and improving their solutions to meet the evolving needs of the industry.In conclusion, Standard Conveyor Speed has established itself as a pioneer in the field of conveyor solutions, setting a new industry standard for efficiency and reliability. With their focus on innovation, customer satisfaction, and sustainability, Standard Conveyor Speed is well-positioned to lead the way in shaping the future of material handling operations.

Different Profiles of Metal Roof Panels: A Comprehensive Guide

Metal Roof Panel Profiles are an essential element of modern architecture and construction. With their sleek and durable design, these profiles provide not only aesthetic value but also excellent protection for buildings. The use of metal roof panel profiles has surged in popularity in recent years, as architects and builders alike recognize their many benefits.{Company Name} is a leading provider of metal roof panel profiles, offering a wide range of options to suit various architectural styles and construction needs. With an unwavering commitment to quality and innovation, {Company Name} has established itself as a trusted name in the industry, delivering premium products that meet the highest standards.One of the key advantages of metal roof panel profiles is their exceptional durability. Made from high-quality materials, these profiles are designed to withstand the harshest environmental conditions, including heavy rain, strong winds, and even fire. This level of resilience not only ensures the long-term protection of the building but also reduces the need for frequent maintenance and repairs, saving time and money for the property owners.In addition to their durability, metal roof panel profiles are also highly versatile. {Company Name} offers a diverse range of profiles, including standing seam, ribbed, and corrugated designs, each with its own unique characteristics and aesthetic appeal. Whether it's for a residential, commercial, or industrial project, these profiles can be customized to fit the specific requirements of the building, providing architects and builders with the flexibility they need to bring their vision to life.Furthermore, metal roof panel profiles are known for their energy efficiency. With proper insulation and reflective coatings, these profiles can help regulate the building's temperature, reducing the need for excessive heating and cooling, and ultimately lowering energy costs. This not only benefits the property owners but also contributes to environmental sustainability by conserving energy resources.Another significant advantage of metal roof panel profiles is their ease of installation. {Company Name} prides itself on delivering profiles that are designed for straightforward and efficient installation, saving time and labor costs for the construction team. This, combined with the long lifespan of these profiles, makes them a practical and cost-effective choice for any building project.Moreover, metal roof panel profiles offer a sleek and modern aesthetic that adds value to any property. Whether it's a contemporary commercial building or a residential home, the clean lines and smooth finish of these profiles create a striking visual impact, enhancing the overall appeal of the structure.{Company Name} is dedicated to providing comprehensive support to its clients, from the initial consultation to the final installation. With a team of knowledgeable and experienced professionals, {Company Name} offers expert guidance and technical assistance to ensure that every project is executed with precision and excellence. The company's commitment to customer satisfaction has earned them a reputation for reliability and integrity in the industry.In conclusion, metal roof panel profiles are an essential component of modern construction, offering durability, versatility, energy efficiency, and aesthetic value. With {Company Name} at the forefront of this industry, architects, builders, and property owners can trust in the superior quality and performance of these profiles, knowing that they are investing in a product that will stand the test of time. As the demand for metal roof panel profiles continues to grow, {Company Name} remains dedicated to providing innovative solutions that meet the evolving needs of the construction market.

Discover the Revolutionary Roller Top Belt with Positrack - A Game-Changing Innovation!

Title: Revolutionary Roller Top Belt With Positrack Revolutionizes Material HandlingIntroduction:In today's fast-paced and highly demanding manufacturing and distribution industries, companies are constantly seeking innovative solutions to optimize efficiency and productivity. A recent breakthrough in material handling comes in the form of the revolutionary Roller Top Belt With Positrack, developed by a leading industry player. This game-changing technology not only enhances the speed and accuracy of material handling operations but also minimizes downtime and product loss. With an unwavering commitment to excellence, the company behind this groundbreaking invention has established itself as a frontrunner in the pursuit of advanced material handling solutions.Innovative Features:The Roller Top Belt With Positrack epitomizes cutting-edge engineering, providing remarkable benefits for various industries. Unlike traditional conveyor belts, this ground-breaking solution incorporates advanced features designed to streamline operations and deliver superior results.One of the key highlights of the Roller Top Belt With Positrack is its unique roller top design. Each seamless roller is precisely engineered to provide optimal traction, ensuring a secure grip on packages of various sizes and materials. This feature minimizes the risk of product slippage, significantly reducing costly product damage and loss.Additionally, Positrack, an innovative tracking mechanism, has been integrated into the conveyor belt system. Utilizing advanced sensor technology, Positrack enables automated precision tracking, reducing the need for manual adjustments and enhancing overall performance. This automated tracking feature guarantees smooth conveyance of materials, minimizing disruption and maximizing operational efficiency.Benefits and Applications:The Roller Top Belt With Positrack offers a multitude of benefits to a wide range of industries. From e-commerce and retail distribution centers to food and beverage production facilities, this game-changing technology ensures seamless material handling operations.By significantly decreasing the risk of product damage, the Roller Top Belt With Positrack safeguards the quality and integrity of goods throughout the supply chain. This not only bolsters customer satisfaction but also reduces financial losses incurred due to damaged or unsellable products.Moreover, the advanced tracking mechanism eliminates the need for frequent manual adjustments, resulting in minimized downtime and increased productivity. The automated system efficiently navigates through various inclines and declines, optimizing workflow efficiency and reducing labor costs.The Roller Top Belt With Positrack's versatility is another testament to its innovation. With its ability to handle products of varying sizes and weights seamlessly, from small packages to larger machinery components, this technology caters to the diverse needs of different industries.Company's Commitment to Excellence:The company behind this groundbreaking invention has consistently demonstrated a commitment to excellence and innovation. With extensive research and development, their expert team has successfully crafted the Roller Top Belt With Positrack, revolutionizing material handling practices in today's industries.The company's dedication to customer satisfaction is underlined by their thorough testing processes and rigorous quality control measures. Each Roller Top Belt With Positrack undergoes comprehensive inspections to ensure reliability, durability, and unrivaled performance, sparing no efforts to meet the highest industry standards.Additionally, the company places great emphasis on sustainability and environmental responsibility. The Roller Top Belt With Positrack is made from high-quality, recyclable materials, reducing the carbon footprint of material handling operations.Conclusion:In a world driven by fast-paced industries, where streamlined operations and efficiency are paramount, the Roller Top Belt With Positrack provides an innovative solution for material handling challenges. By combining seamless roller top design with automated tracking mechanisms, this revolutionary technology enhances the speed, accuracy, and reliability of material handling operations. As the company continues to lead the way with advanced solutions, the Roller Top Belt With Positrack promises a brighter future for material handling across industries worldwide.

Top Flat Chain Conveyor: A Versatile Material Handling Solution

The use of Flat Top Chain Conveyor systems has become increasingly popular in the manufacturing and packaging industries due to their efficiency and versatility. In recent years, a leading company in the field of material handling and conveyor systems has been at the forefront of the development and implementation of these innovative systems. With a strong reputation for providing high-quality solutions to a wide range of industries, this company has continued to push the boundaries of what is possible in terms of conveyor technology.The Flat Top Chain Conveyor systems offered by this company are designed to handle a wide range of products and can be customized to meet the specific needs of each customer. These systems are ideal for use in food processing, automotive, pharmaceutical, and other industries where high-speed and high-volume conveyance is required. The modular design of these conveyors allows for easy installation and maintenance, and they can be seamlessly integrated into existing production lines.One of the key features of the Flat Top Chain Conveyor systems offered by this company is their ability to accommodate heavy loads while maintaining smooth and reliable operation. The sturdy construction and precision engineering of these conveyors make them suitable for handling even the most demanding of applications. Additionally, they can be equipped with a range of accessories such as side guides, product diverters, and accumulation zones to further enhance their functionality.In addition to their robust design, these conveyor systems are also known for their energy efficiency and low maintenance requirements. By utilizing state-of-the-art drive systems and components, this company has been able to develop conveyor solutions that minimize energy consumption while maximizing productivity. Furthermore, their commitment to quality and reliability means that customers can expect minimal downtime and long-term performance from their Flat Top Chain Conveyor systems.Perhaps one of the most impressive aspects of this company’s conveyor systems is their adaptability to different production environments. Whether it be a cleanroom, a freezer, or a high-temperature setting, these conveyors are designed to operate flawlessly in a variety of conditions. This versatility has made them a popular choice for companies looking to optimize their manufacturing processes and improve overall efficiency.To complement their range of conveyor systems, this company also offers a comprehensive suite of services including system design, installation, training, and ongoing support. Their team of experienced engineers and technicians work closely with customers to develop tailored solutions that address their specific material handling needs. This commitment to customer satisfaction has earned them a strong reputation in the industry and has helped them to build long-lasting relationships with their clients.As the demand for advanced material handling solutions continues to grow, this company remains committed to driving innovation and setting new standards for conveyor technology. With their proven track record of delivering reliable and efficient systems, they are well-positioned to remain a leader in the field for years to come.In conclusion, the Flat Top Chain Conveyor systems offered by this company represent a significant advancement in material handling technology. Their robust design, energy efficiency, and adaptability make them a standout choice for companies looking to streamline their production processes. With a strong focus on customer satisfaction and a reputation for excellence, this company is poised to continue leading the way in the conveyor industry.

What is the typical speed of a conveyor belt?

Conveyor belts are an essential part of many industrial and manufacturing processes, helping to transport materials and products from one point to another with ease and efficiency. And when it comes to conveyor belt speed, it is a crucial factor in determining the overall productivity and performance of the system.Typical conveyor belt speed can vary depending on the specific application and the type of material being transported. However, in general, the typical speed range for conveyor belts is between 100 and 500 feet per minute. This speed range ensures that materials are moved quickly and efficiently without causing damage or disruption to the production process. It also allows for optimal performance and productivity in various industries such as food processing, automotive manufacturing, and logistics.One company at the forefront of conveyor belt technology is {Company name}. With a strong commitment to innovation and quality, {Company name} has been a leading provider of conveyor belt solutions for a wide range of industries for over 50 years. Their dedication to research and development has allowed them to continually improve their products and services, offering customers the most advanced and reliable conveyor belt systems available on the market.{Company name}'s conveyor belt systems are designed to meet the specific needs and requirements of their customers, providing solutions for various applications including heavy-duty industrial environments, food processing facilities, and airport baggage handling systems. Their conveyor belts are engineered to deliver optimal performance, durability, and reliability, ensuring smooth and efficient material handling operations.In addition to their high-quality conveyor belt systems, {Company name} also offers a comprehensive range of services including installation, maintenance, and technical support. Their team of highly skilled and experienced professionals is dedicated to providing exceptional customer service and ensuring that their products perform at their best throughout their lifecycle.With a strong focus on sustainability and environmental responsibility, {Company name} is also committed to developing eco-friendly conveyor belt solutions. They invest in research and development to create products that minimize energy consumption and reduce environmental impact, while also improving the overall efficiency and performance of their systems.In conclusion, conveyor belt speed is a critical factor in the overall performance and productivity of material handling systems. With a typical speed range of 100 to 500 feet per minute, conveyor belts play a key role in various industries by efficiently transporting materials and products. {Company name} is a leading provider of conveyor belt solutions, offering advanced and reliable systems designed to meet the specific needs of their customers. With a strong commitment to innovation, quality, and sustainability, {Company name} continues to lead the way in conveyor belt technology, providing exceptional products and services for a wide range of applications.

Different Types of Metal Siding Profiles for Your Home

Metal Siding Profiles have been making waves in the construction and architecture industries, providing durability and aesthetic appeal to residential and commercial buildings alike. With a variety of profiles and finishes to choose from, Metal Siding Profiles has become a leading choice for architects, builders, and homeowners looking for a sleek and modern exterior solution. Founded in 1998, Metal Siding Profiles has established itself as a trusted supplier of metal siding products. The company prides itself on delivering top-quality products that are built to last, with a focus on innovation, sustainability, and customer satisfaction. With a state-of-the-art manufacturing facility and a team of experienced professionals, Metal Siding Profiles is well-equipped to meet the needs of its customers and provide tailored solutions for a wide range of projects.The versatility of Metal Siding Profiles' products is a key selling point for the company. Whether it's a residential renovation, a new commercial development, or an industrial facility, Metal Siding Profiles offers a range of profiles, colors, and finishes to suit any design aesthetic. From traditional to contemporary, their metal siding products can be customized to create a unique and eye-catching facade for any building.One of the main advantages of metal siding is its durability. Metal Siding Profiles' products are designed to withstand the elements, including harsh weather conditions, UV exposure, and temperature fluctuations. This means that buildings clad in metal siding require minimal maintenance and are built to stand the test of time, making them a cost-effective and practical choice for both residential and commercial applications.In addition to their durability, Metal Siding Profiles' products are also environmentally friendly. The company is committed to sustainability and has taken steps to reduce its environmental impact through responsible manufacturing processes and material sourcing. Metal siding is also recyclable, making it a sustainable choice for those looking to minimize their carbon footprint.Metal Siding Profiles offers a range of installation options to ensure a seamless and professional finish. Their products can be installed using various techniques, including concealed fasteners or visible fasteners, depending on the desired aesthetic and performance requirements. This flexibility makes Metal Siding Profiles' products suitable for a wide range of architectural styles and project specifications.In recent years, Metal Siding Profiles has seen a surge in demand for its products, as architects and builders increasingly recognize the benefits of metal siding. Its use of metal siding has extended beyond traditional commercial and industrial applications, with an increasing number of residential projects choosing metal siding for its sleek and modern look. Homeowners are drawn to the low maintenance and longevity of metal siding, as well as the wide range of design options available.Metal Siding Profiles has also been at the forefront of innovation in the industry, introducing new finishes and profiles to meet the evolving needs of its customers. The company regularly invests in research and development to stay ahead of industry trends and offer cutting-edge solutions to the market. This commitment to innovation has helped Metal Siding Profiles maintain its position as a leading supplier of metal siding products.As the construction and architecture industries continue to embrace sustainable and durable building materials, the demand for metal siding is expected to grow. With its proven track record of delivering high-quality products and its commitment to innovation and sustainability, Metal Siding Profiles is well-positioned to meet this demand and continue to be a top choice for architects, builders, and homeowners alike.

Efficient Chicken Butcher Machine Streamlines Poultry Processing for Greater Productivity

Title: Revolutionary Chicken Cutting Machine Enhances Poultry Processing EfficiencyIntroduction:In a bid to enhance efficiency and productivity in the poultry processing industry, a renowned company has developed a groundbreaking Chicken Butcher Machine. This cutting-edge technological innovation is poised to revolutionize the way chicken is prepared and processed, streamlining the operation to meet the growing demand for poultry products worldwide. This article will delve into the key features and benefits of this game-changing chicken cutting machine, while also exploring the future implications for the industry.Streamlining Chicken Processing:With the increasing global demand for poultry products, it has become imperative for poultry processing facilities to adopt cutting-edge technologies that improve efficiency, minimize waste, and maximize output. This is where the Chicken Butcher Machine comes into play. Incorporating advanced automation and precision cutting techniques, this revolutionary machine significantly reduces the labor-intensive and time-consuming process of chicken cutting and butchering.Key Features:The Chicken Butcher Machine combines engineering mastery with advanced robotics, ensuring a streamlined cutting process from start to finish. Equipped with a high-speed conveyor system, the machine moves the poultry carcasses through a series of precision-cutting stations, each configured to perform a specific task. These tasks may include splitting, deboning, and portioning the chickens into desired cuts efficiently and hygienically.The machine's carefully designed blades and sensors ensure consistent cuts, optimizing yield and reducing waste. Additionally, a state-of-the-art vision system enables the machine to inspect each chicken, ensuring only the highest quality products are processed.Benefits for Poultry Processors:1. Enhanced Efficiency: The Chicken Butcher Machine eliminates the need for manual labor-intensive chicken cutting and enhances overall processing efficiency. Designed to achieve high-speed cutting and deboning, the machine can process a significant volume of poultry carcasses in a shorter timeframe, boosting productivity.2. Improved Yield: With precision cutting techniques and a vision system in place, the machine ensures optimal yield and minimal product waste. Each chicken is meticulously inspected and processed, guaranteeing consistent quality cuts and reducing the margin of error during butchering.3. Hygiene and Food Safety: As a crucial aspect of the poultry processing industry, hygiene and food safety are paramount. The Chicken Butcher Machine is designed to meet stringent sanitary standards, incorporating easy-to-clean stainless steel surfaces and automated cleaning processes. This ensures that the machine is always maintained in a hygienic condition and reduces the risk of bacterial contamination.4. Labor Savings: By automating the chicken cutting process, the Chicken Butcher Machine minimizes the dependence on manual labor. This not only reduces the overall labor costs but also eliminates the risk of fatigue-related errors and injuries.Future Implications:The development and widespread adoption of the Chicken Butcher Machine are expected to reshape the poultry processing industry globally. As the demand for poultry products continues to rise, the ability to process and deliver products efficiently is vital. With its advanced automation and precision cutting capabilities, the machine can help meet this growing demand, driving economic growth while ensuring food safety and hygiene.Conclusion:The innovative Chicken Butcher Machine presents an exciting advancement in the poultry processing industry. Its incorporation of cutting-edge technology, precision cutting techniques, and automated systems contribute to enhanced productivity, improved yield, and heightened food safety. As more processing facilities embrace this groundbreaking innovation, the poultry industry is poised to witness unprecedented growth and efficiency, catering to the increasing demand for poultry products worldwide.