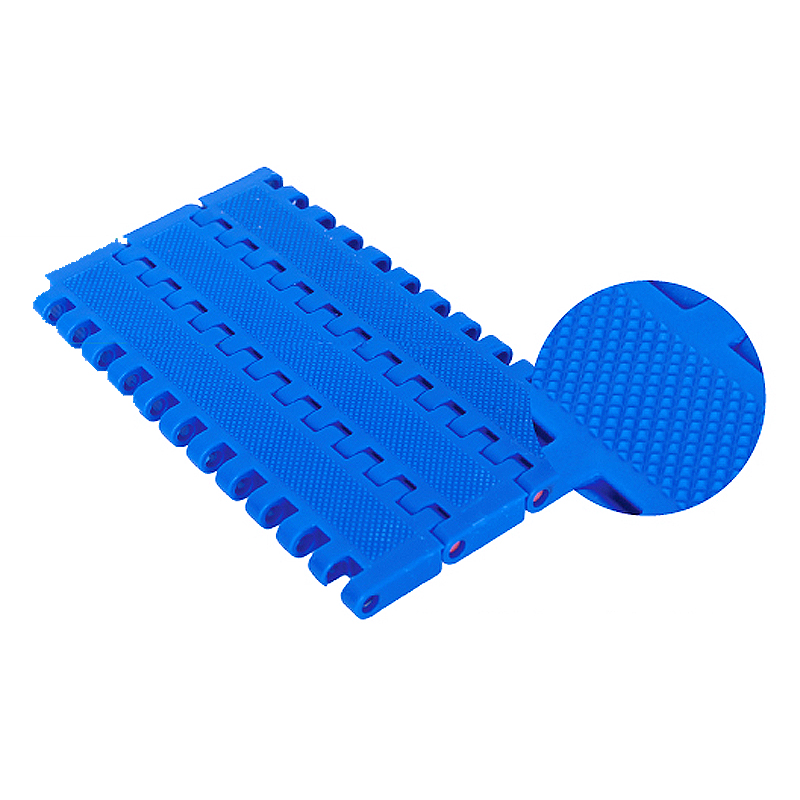

Belt Material:POM / PP / PE Belt Pitch:12.7mm Open Area:18%

Belt Material:POM / PP / PE Belt Pitch:12.7mm Open Area:18% | Belt type | Material | Temperature range | Working load(max.) | Weight | Backflex radius(min.) | |

| dry | wet | N/m(21℃) | Kg/m2 | mm | ||

| M1230 | POM | 5 to 90 | 5 to 65 | 16000 | 7.8 | 10 |

| PP | 5 to 105 | 5 to 105 | 11000 | 5.4 | ||

| PE | -70 to +65 | -70 to +65 | 7000 | 5.7 | ||

| Sprocket type | Nr. of teeth | Pitch diameter | Outside diameter | Hub diameter | Bore |

| H (mm) | C (mm) | M(mm) | DF (mm) | ||

| 1-1200-10-20 | 10 | 41.2 | 41.0 | 20.0 | φ20 |

| 1-1200-15-30 | 15 | 62.4 | 62.5 | 30.0 | φ30 |

| 1-1200-15-25x25 | □25x25 | ||||

| 1-1200-19-35 | 19 | 78.8 | 79.0 | 20.0 | φ35 |

| 1-1200-19-30x30 | □30x30 | ||||

| 1-1200-22-30 | 22 | 89.5 | 90.1 | 30.0 | φ30 |

| 1-1200-22-30x30 | □30x30 | ||||

| 1-1200-28-40 | 28 | 116.5 | 116.9 | 49.0 | φ40 |

| 1-1200-28-40x40 | □40x40 | ||||

| 1-1200-36-40 | 36 | 149.8 | 150.4 | 49.0 | φ40 |

| 1-1200-36-60x60 | □60x60 |

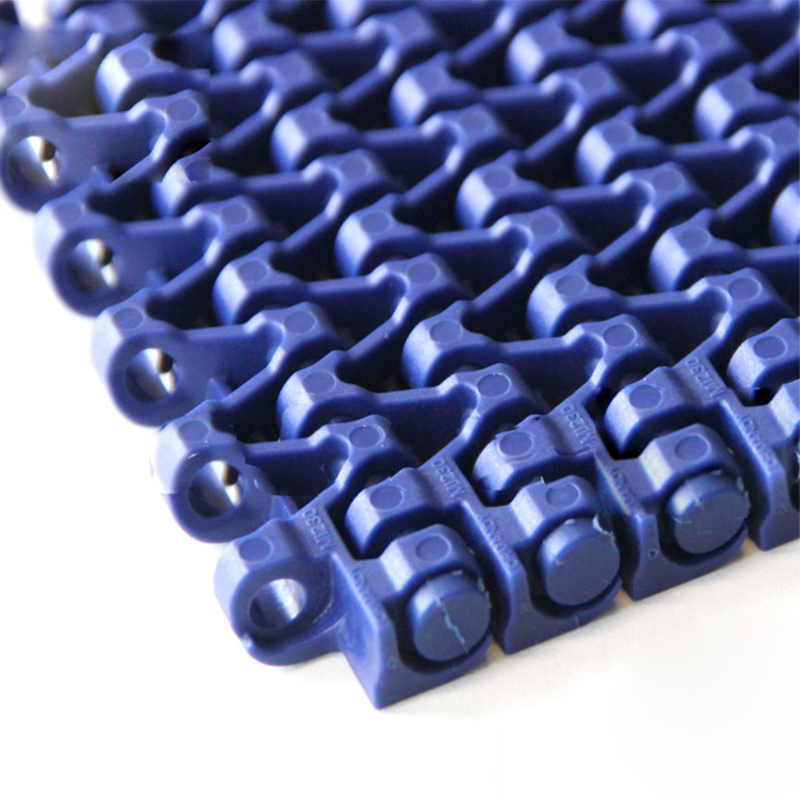

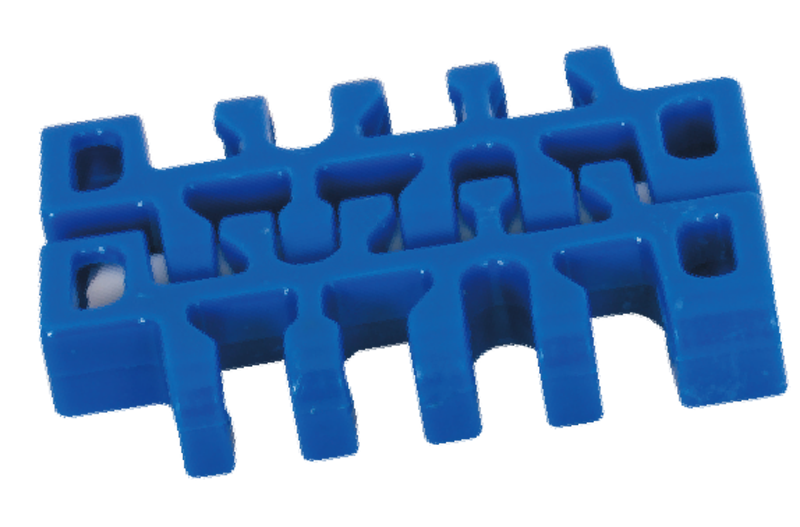

A customer service team of more than 20 people will provide you with dedicated personnel to answer every question you have.Modular belts are constructed with modules molded from thermoplastic materials connected with solid plastic rods. Except for narrow belts (one complete module or less in width),all are built with the joints betweenmodules staggered with those of adjacent rows in a "bricklayed" fashion. This structure can enhancetransverse strength and it is easy for maintain. The total plastic and cleanable design can solve the steel belts easily polluted. Now the cleanable design makes the belts very suitable for food industry area as well. Also there are be widely used in many otherindustries,such as container making,pharmaceutical and automotive,lines of battery and so on.Large production base, covering an area of 20000 square meters, standardized production and operation mode, timely delivery, low price and good quality

A customer service team of more than 20 people will provide you with dedicated personnel to answer every question you have.Modular belts are constructed with modules molded from thermoplastic materials connected with solid plastic rods. Except for narrow belts (one complete module or less in width),all are built with the joints betweenmodules staggered with those of adjacent rows in a "bricklayed" fashion. This structure can enhancetransverse strength and it is easy for maintain. The total plastic and cleanable design can solve the steel belts easily polluted. Now the cleanable design makes the belts very suitable for food industry area as well. Also there are be widely used in many otherindustries,such as container making,pharmaceutical and automotive,lines of battery and so on.Large production base, covering an area of 20000 square meters, standardized production and operation mode, timely delivery, low price and good quality